C4 Corvette - “The Arrival Of A Future King”

Research & Complete Reference Guide

Basics / The Story / Timeline / MY Research / MY Guides / Buyer's Guide / The Market / Vids & Pics / Latest / Tech Research

The C4: 1984 - 1996

With a production run of fifteen years under it’s belt, there were few within General Motors who questioned the absolute necessity to retire the third generation Corvette in favor of making way for a fourth generation model – the C4. After all, the C3 had been largely based on mechanical designs that were originally implemented in 1963 with the onset of the C2 Stingray.

Few real changes had been made to it’s design, save for changes being made in favor of decreased exhaust emissions, increased fuel economy and increased safety – most of which were directed solely by government issued mandates. Even the 1982 Corvette, which was known more for its sophistication and luxurious design than for the handling and horsepower of its forefathers, remained largely structurally and mechanically similar to the ’63 Corvette.

In addition to the stagnation of mechanical development that had occurred over the previous two decades, there was a genuine demand from the public that General Motors rethink the design of their “American Sports car.” After many years of rumors that an “all new Corvette” had been under development, legions of Corvette fans were eager to see something completely new roll out of Bowling Green’s Corvette assembly plant. In 1984, the faithful would get their wish.

Few cars in history have ever been more eagerly anticipated than the arrival of the C4 Corvette. This new ‘Vette was a completely original design – from top to bottom – and was a contemporary interpretation of the American Classic. Admittedly, it still was not the “car-of-the future-here-today” that General Motors had eluded to secretly developing since the early 1960’s, but it was a brand-new Corvette nonetheless, and one that was bound to turn a lot of heads.

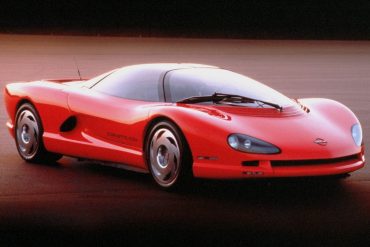

Work on the C4 Corvette actually began in 1978, shortly after General Motors management cancelled plans to replace the existing C3 Corvette with a production version of the Aerovette show car – a car that General Motors engineers had been developing since 1973. Unlike generations past, where Corvette designers and engineers would often clash on “form versus function”, the team behind the design of the C4 Corvette was one of the most cooperative partnerships between designer and engineer that General Motors has ever seen – before or since.

C4 Corvette Basics

Generation: C4 Corvette / Body Styles: 2 Door Coupe (1984 - 1996), 2 Door Convertible (1986 - 1996) / Production Years: 1984-1996 / Designed by: David R Mclellen, Jerry Palmer / Production: 358,180 (1984-1996) / Model Years: 1984, 1985, 1986, 1987, 1988, 1989, 1990, 1991, 1992, 1993, 1994, 1995, 1996

The C4 Corvette Story & Details

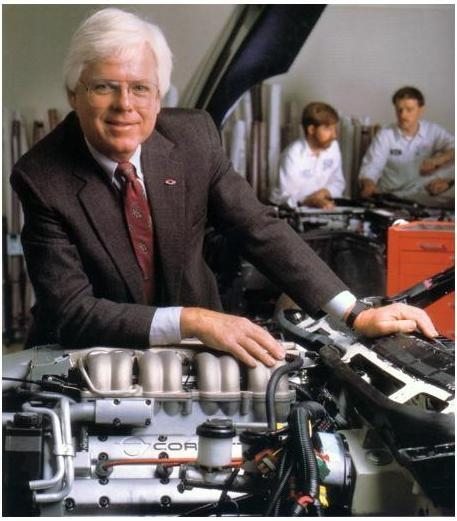

Heading the program behind the design of the C4 was Corvette Chief Engineer David R. McLellan (who had succeeded Zora Arkus-Duntov in 1975) and Lead Designer Jerry Palmer, (who had been recently promoted as the new head of “Chevrolet Production Studio Three” after Bill Mitchell’s retirement from GM in 1977). While further guidance would come from GM’s Director of Design, Chuck Gordon and Vice-President of Design Staff, Irv Rybicki, it was ultimately McLellan and Palmer who would have to proceed with the many challenges about to be set before them. General Motors top brass recognized that it was vital for McLellan and Palmer to work well together if the C4 was going to be built with a high enough level of quality to compete in a global market of emerging car superstars.

This was doubly important because not only were there high performance expectations in the balance, but this new https://www.corvsport.com/ was going to be considerably more expensive than any of its predecessors. According to Palmer, the mission statement adopted by the development duo for the C4 Corvette was that, with regards to design, “form follows function.” Although this had often been the “official dictum” of automakers for generations, the shared consensus between Palmer and McLellan was that if the new Corvette was to remain competitive with the latest European and Japanese sports cars, they would have to adhere to this sentiment.

Already, these manufacturers had gained a solid foothold on the American market with cars like the Ferrari 308, the Lotus Esprit and most especially the German line up of comparably priced models that included the Porsche 911 Turbo, Porsche 928 and even the competitively priced Porsche 924 (and later, the more agile and performance driven Porsche 944.)

While McLellan’s engineers were to set about laying out the technical intricacies of the car, Palmer’s staff would begin shaping the car’s appearance. For both, the design brief held by GM’s top brass was imposing. First, and most obviously, the new C4 had to look like a Corvette; it couldn’t break with the model’s traditional styling cues. Drivelines would be carried over, and though the new body design could be physically smaller outside, the car had to offer more interior room. Improved outward vision and less air resistance (drag) were additional goals that had to be met.

Second, they had to eliminate the deficiencies that had been identified (and largely criticized) in earlier generations of Corvette. Third, the car needed to provide its passengers with more interior space, (which had functionally proved a definite shortcoming of previous Corvettes). Fourth – and perhaps most importantly – they had to develop a car that would slice through the air with superior aerodynamics and provide better handling than any of Corvette’s earlier models. From the onset, it was decided that the C4 Corvette would not simply be a re-design of previous models, but would instead be a new car that featured the “look and feel” of its predecessors.

Although General Motors had placed some fairly stringent demands of the new Corvette, the design/styling of the car progressed fairly quickly. Early sketches developed by Palmer were used as the basis for the development of a clay model of the conceptual C4. This first model was completed in September, 1978. By mid-November, 1979 – a mere fourteen months later – the conceptual design of the C4 was essentially complete, save for the look and placement of tail lamps, front-fender trim, and nose contour.

A decision early on in the design process was to mount the steering linkage further forward than originally envisioned. By doing so, the engineering team was able to lower the placement of the engine in the chassis. This corresponded into a lower hood line, which produced better visibility and reduced the overall frontal area of the car. The latter of these improvements resulted in a considerable reduction in aerodynamic drag (which is not the drag coefficient alone but the product of the drag coefficient multiplied by the car’s total frontal area).

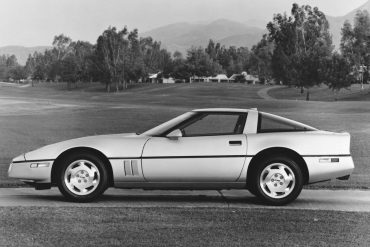

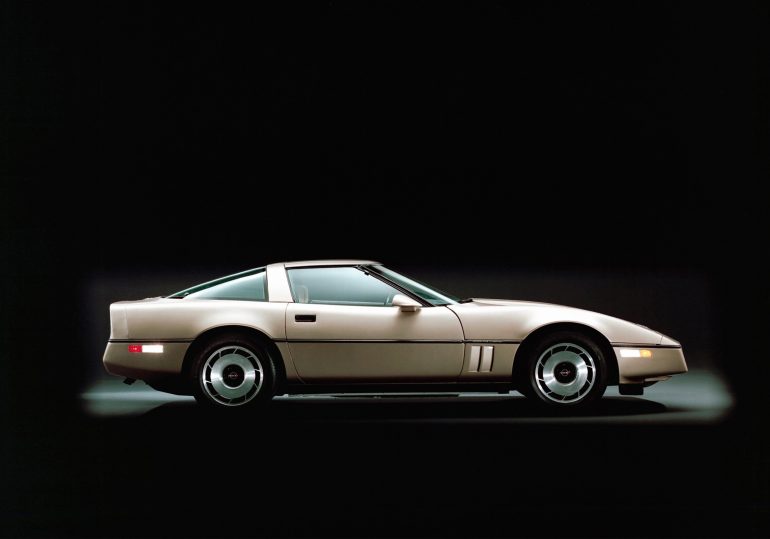

As the conceptual design came together, what ultimately emerged was unmistakably a Corvette. Ironically, the overall dimensions of the car were actually smaller than its predecessors, although it still maintained the appearance of a relatively large car, due mostly to the longer hood, the forward placed front end and other altered proportions. In actuality, the overall length of the Corvette was reduced by an impressive 8.8 inches despite a mere 2 inch cut in wheelbase – from 98.0 inches (the C3) to 96.0 inches (the C4 prototype) – with just a 1.7-inch reduction in front overhang.

Some of the key contributors to the Corvette’s apparent reduction in size was due to the 64-degree windshield angle (as measured from the vertical plane) which at that time was the steepest windshield angle for any American production car. In addition, the base of the windshield was dropped 1.5 inches lower than its predecessor and moved slightly further forward than before. This also allowed the beltline of the car to be lowered, giving the C4 prototype a slimmer, glassier appearance. Lastly, the tail length of the Corvette was reduced by 5.2 inches which helped give the illusion of a longer hood even though the hood was actually shorter than that of the C3.

Perhaps the most notable change in the new Corvette’s appearance was the overall increase in the car’s width. One of the notable characteristics of the C3 Corvette had been the “pinched-waist” midsection that resided between the flared front and rear fenders.

The C4 design eliminated this feature, and was replaced instead by a smoother, more streamlined contour. The flared fenders were still present, although when combined with the flat wheels and lower-sidewall profile tires, it gave the car a more “hunkered down” appearance. No longer interrupted by the fenders, the beltline wrapped its way uninterrupted from the front windshield towards a near-vertical Kammback style tail (a design style that calls for a body with smooth contours that continues to a back end that is abruptly cut off). The Kamm tail was fitted with the traditional pairing of rounded taillights.

The 1973 Aerovette Prototype

The 1973 Aerovette Prototype David R. McLellan, Corvette Chief Engineer of the C4 Corvette.

David R. McLellan, Corvette Chief Engineer of the C4 Corvette. Exposed View Of The Conceptual C4 Corvette.

Exposed View Of The Conceptual C4 Corvette.Unbeknownst to consumers at the time, the C4 would not arrive in time to celebrate Corvette’s 30th anniversary. It was decided early on that the C4 would debut as an early 1984 model. While the C4 would technically be available late in 1983, all models would be identified as 1984 models. By failing to produce the Corvette in 1983, General Motors lost a great marketing opportunity to produce a special 30th anniversary edition.

DID YOU KNOW?

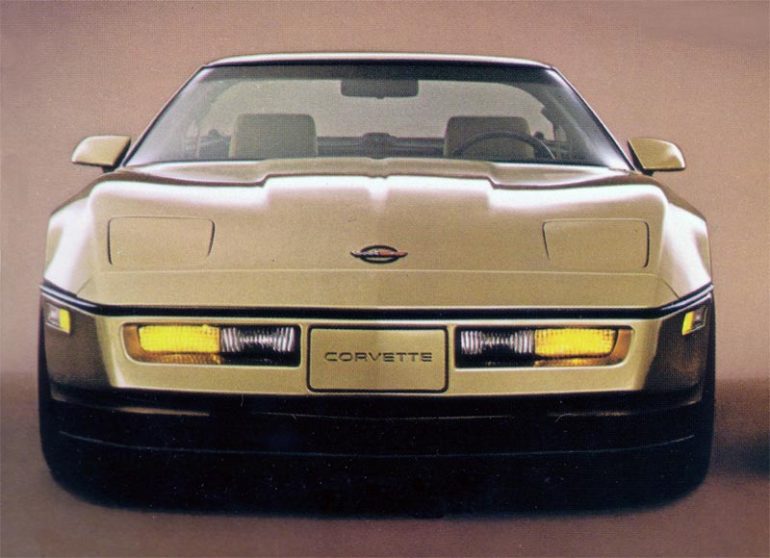

Front View of the Conceptual C4 Chevrolet Corvette. (Image Courtesy of GM Media.)

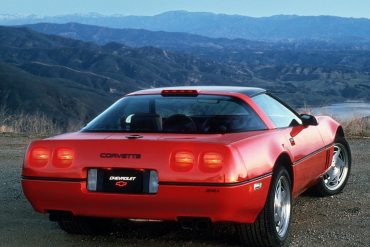

Front View of the Conceptual C4 Chevrolet Corvette. (Image Courtesy of GM Media.) Rear View of the Conceptual C4 Chevrolet Corvette. (Image Courtesy of GM Media.)

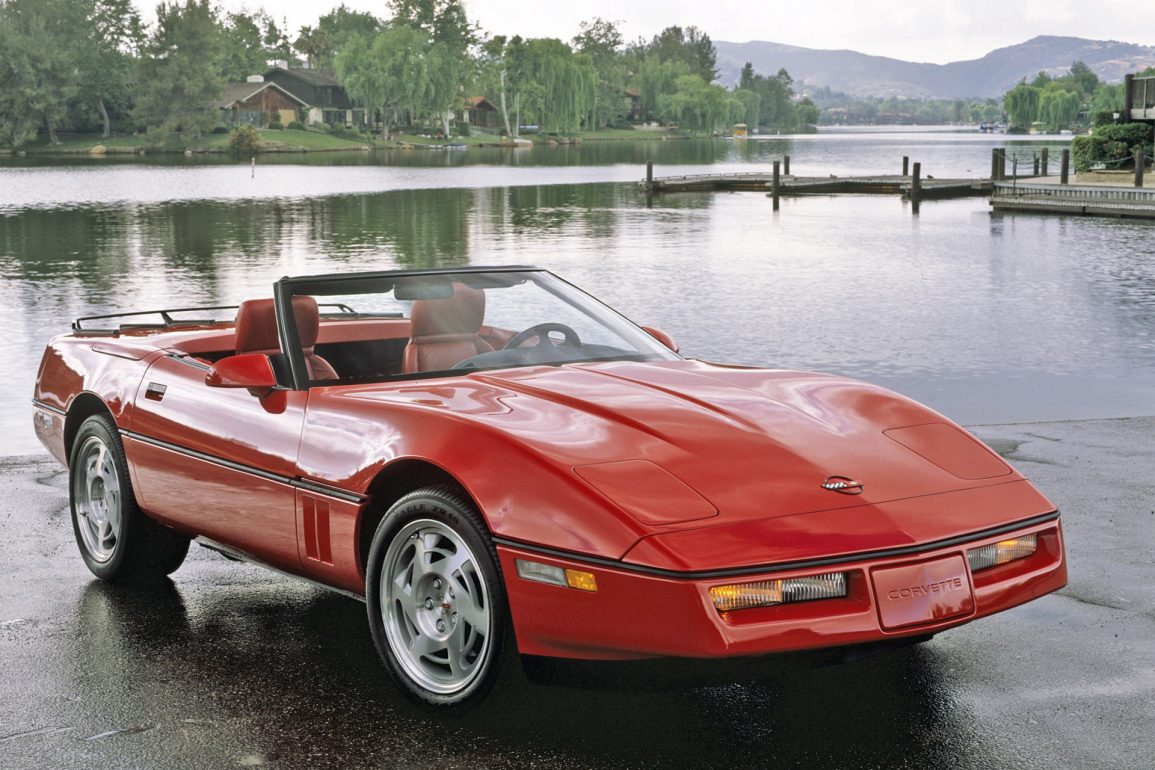

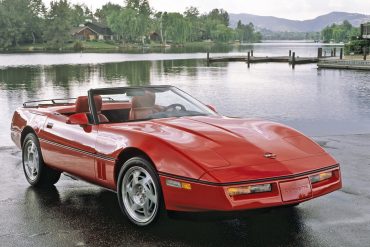

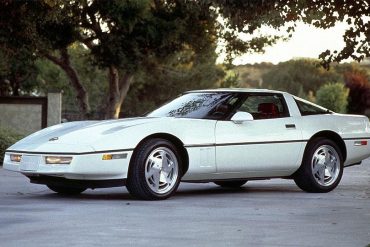

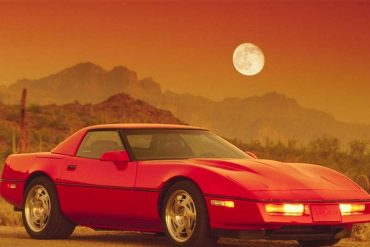

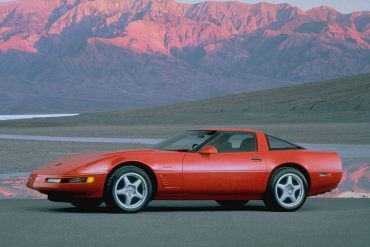

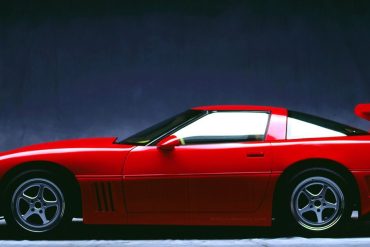

Rear View of the Conceptual C4 Chevrolet Corvette. (Image Courtesy of GM Media.) Red C4 Chevrolet Corvette

Red C4 Chevrolet Corvette A single piece, removable roof panel was introduced for the first time on the C4 Corvette.

A single piece, removable roof panel was introduced for the first time on the C4 Corvette. Interior of the 1984 C4 Corvette. Credit: Wikimedia Commons

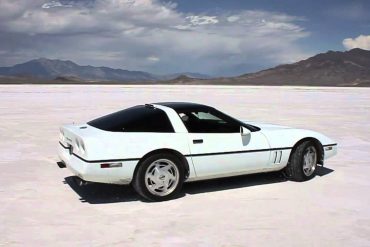

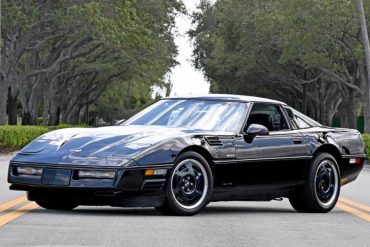

Interior of the 1984 C4 Corvette. Credit: Wikimedia Commons Chevrolet Corvette C4 1984

Chevrolet Corvette C4 1984 Example of the "Unidirectional Wheel" Developed for the C4 Corvette.

Example of the "Unidirectional Wheel" Developed for the C4 Corvette. C4 Engine Bay

C4 Engine Bay The Cross-Fire Injection emblem became a unique identifier of the 1984 C4 Corvette. Only two Corvettes used Cross-Fire Injection - the 1982 C3 and the 1984 C4 models.

The Cross-Fire Injection emblem became a unique identifier of the 1984 C4 Corvette. Only two Corvettes used Cross-Fire Injection - the 1982 C3 and the 1984 C4 models.

C4 Corvette Continues Development

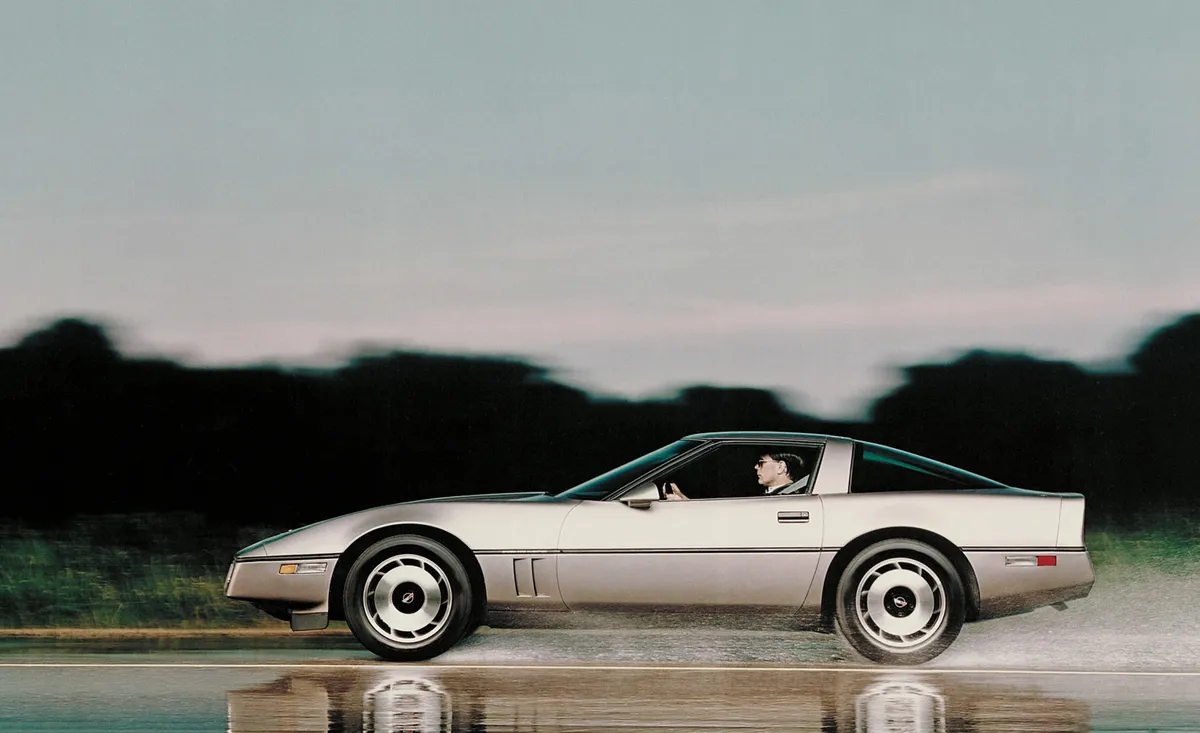

Effectively, the new profile of the Corvette was that of a wedge, and one which was aesthetically pleasing while being considered functional by General Motors

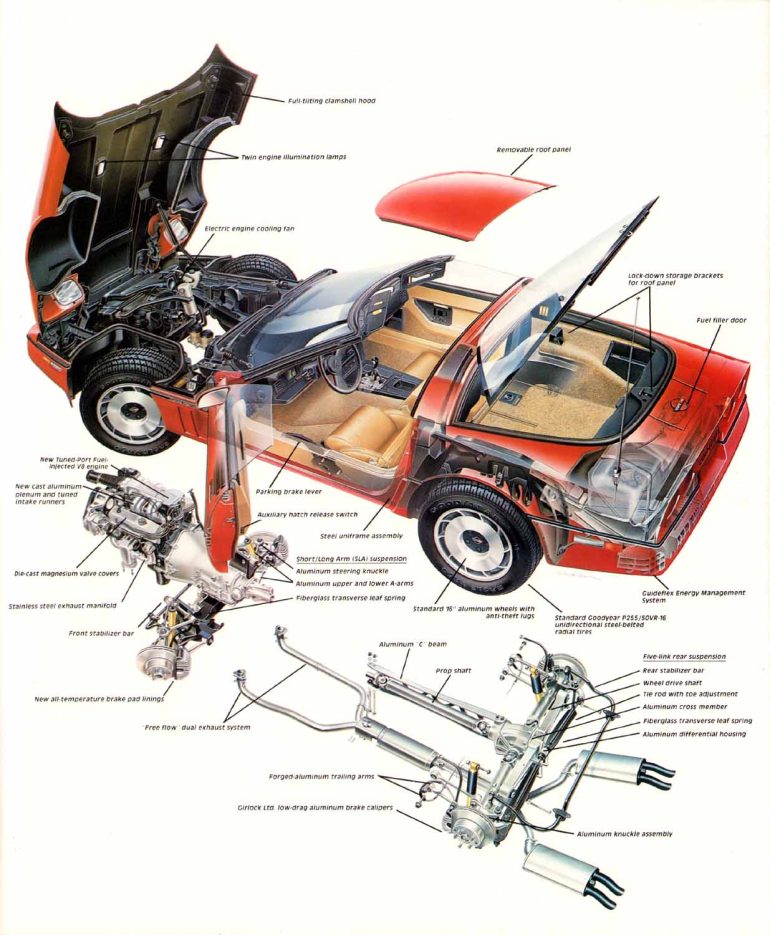

One of the great examples of the “form follows function” design mentality was the development of an all-new clamshell-type hood. While the “clamshell” hood was part of the conceptual design from the start, the Design and Engineering teams had established a way of blending appearance with practicality by allowing for a nearly seamless integration of the hood with the front fender tops when it was closed, while also providing unparalleled access to the engine compartment when opened, by lifting to a near-vertical position.

A second, equally important example following the same idiom was the development of the C4 Corvette’s full perimeter rub strip. New to the Corvette, the rub strip was installed at roughly the midpoint of the car’s body height and tied the front and rear bumpers together visually, while also concealing the one major seam in the new fiberglass body. Similarly, it also aided in the concealment of the shut-lines around the clamshell hood, thereby giving the entire car a nearly seamless appearance.

Perhaps, though, the greatest example of “form follows function” was that of General Motor’s boastful claim that the C4 Corvette was (at least partially) shaped and designed inside of a wind tunnel. Due to extensive wind-tunnel testing, the new Corvette achieved a much lower drag coefficient than its predecessors. With a drag coefficient number (Cd) number of just 0.34, the C4 Corvette showed a 23.7 percent reduction in drag when compared to the 1982 Corvette (whose Cd number was 0.44). In the end, the new Corvette’s aerodynamic appearance was genuine.

Further conceptual design elements found their way into the new C4. Perhaps one of the most influential for all future Corvettes was the replacement of the traditional T-top roof panels (which had been a standard on Corvette coupes for the past 15 years) with a one-piece removable roof panel. The roof panel would be secured in place at four attachment points – two on the windshield header and two on the rear roof hoop (or “B-pillar” as it’s more commonly known).

As on early “Sharks”, the panel could be stowed by being inserted into special slots built into the top of the luggage area (which resided directly behind the driver and passenger seats. The radical new design of the C4 Corvette did not end with the exterior of the car. With its futuristic styling and refined lines, the design team knew that the interior would have to be equally enthralling. Under the direction of Pat Furey, head of General Motor’s Interior Design Group, the new Corvette’s interior was dominated by a high-tech, futuristic instrument panel and the usual tall center tunnel/console. Instrumentation was now directly in front of the driver instead of being strewn across the dashboard and center console (as was often the case on earlier models). All of the dashboard displays were high-tech electronic displays developed and supplied by AC-Delco.

Road and engine speeds were monitored by both graphic analog and digital displays. Between these was a sub-panel with digital engine-function readouts, including a vertical bar-graph fuel gauge. A quartet of switches, (to the left of a bank of warning lights in the center of the dash), allowed the sub-panel to display up to four additional readouts. Included in these readouts was instantaneous and average miles per gallon, a trip odometer, engine temperature, oil pressure and temperature, fuel range, and electrical system voltage. The displays could be changed from American-standard to metric values at the flip of a switch.

The center console of the Corvette housed the heat/vent/air conditioning as well as the audio system controls. A Delco AM/FM-stereo radio was to be a standard option with the new C4, although optional upgrade packages were to be introduced for those who were looking for more premium sound. While such upgrades are commonplace today, the C4 Corvette was one of the first sports cars to focus on the entertainment aspects of motoring.

High back bucket seats were specially designed for the new Corvette as well. While bucket seats were a standard feature on all Corvettes since it’s beginning, the C4 was the first Corvette ever to offer reclining seats. The seats would come standard with cloth trim, though it was decided early on that an optional leather package would be included when the car became commercially available to order. Another option that was to be offered would be the latest in seating technology supplied by Lear-Siegler (an advanced technologies company of that era). These optional seats would provide added electric adjustment for backrest angle and would enable the seat cushion to bolster in and out, plus they included a powered three stage lumbar support adjuster using inflatable bladders that could be air -fed or –bled to achieve the proper driving contour for it’s passengers.

Just as General Motors had placed stringent demands on the aesthetic appearance/design of the car, the infrastructure of the Corvette – from engine and drive train to steering and suspension – was about to be completely re-engineered from the ground up. For McLellan (and his engineering team), the task of engineering a new Corvette would be anything but simple.

Upon the completion of the engineering/design review with General Motors executives, McLellan returned to his engineering group with the many challenges that they were to incorporate into the re-engineering of the new Corvette. They decided to start by adjusting the “T-point”. The “T-point” is the position of the driver’s hip joint relative to the interior and the rest of the car. Collectively, it was decided that the “T-point” should be raised an inch and moved an inch (or more) towards the rear of the car. By raising its position upward, driver visibility was increased. Further, this change would enable the chassis to be sit higher and have greater ground clearance than earlier models. By moving the “T-point” towards the rear of the car, driver legroom was increased, adding to operator comfort and creating more overall cabin space.

The Corvette’s old perimeter-type ladder frame was to be replaced by a steel backbone design. The Corvette’s “spine” was composed of a C-section beam which connected to the differential and supported the driveshaft. This revision to the frame reduced its weight and opened up more cockpit room by eliminating the transmission and differential cross members. Further, it permitted the exhaust system to be run beneath the driveshaft instead of alongside it, thereby allowing the engineering and design teams to achieve a lower roof-line without any loss of headroom. By passing the exhaust system, with its attendant catalytic converters, along the broad, central tunnel that carried the drive shaft between the area in which the seats would eventually reside, he brought the floor of the passenger compartment down to ground clearance level.

Welded to this backbone was what Chevy referred to as an “integral perimeter-birdcage unitized structure” or “uniframe”. This was a first for Corvette, as all older Corvettes had utilized the older discipline of “body on frame” construction, where the body of the car was literally bolted to the frame of the car as two separate – but integrated – units. For the C4, the frame was integral with the chassis and was the first to utilize modern unit body construction. The “birdcage” frame formed the windshield and door frames, the lower A-pillar extensions, the rear cockpit wall, the rocker panels and the front sub-frame. It also included a “hoop” above and behind the cockpit with provided both additional rigidity and a hinge point for the lift-up rear window. Galvanized both inside and out for the best available corrosion resistance, this structure effectively “comprised a skeleton” onto which the outer fiberglass panels would attach. The basic structural assembly was completed by attaching a bold-on front suspension carrier and bolt-on extensions for the back bumper.

By developing a more rigid and structurally integrated frame, McLellan’s staff was able to begin reworking the Corvette’s suspension for greater handling precision. The front end of the Corvette continued to utilize the unequal-length upper-and-lower A-arm arrangement, although there was a small, but dramatic, change. Instead of utilizing a coil spring on each side of the vehicle, a single, reinforced fiberglass leaf spring was mounted transversely between the two lower arms, similar to those in the rear of a larger vehicle – like a van or a truck. Also integrated into the suspension was a standard, 20-millimeter roll bar.

Additional changes were implemented for the rear suspension. In 1966, Zora Arkus-Duntov had introduced an independent suspension system that included a three-link geometry, which became a standard for the rear suspension of Corvettes for the next 18 years. As the C4 continued development, Duntov’s three-link geometry was abandoned for an even more sophisticated five-link design. This new suspension design included upper and lower longitudinal links between the body and hub carriers, twin lateral strut rods tying the differential to the hub carriers, another transverse plastic leaf spring (of the type used since 1981), and the customary U-jointed half-shafts and rear tie rods.

General Motors standard recirculating-ball steering system was to be replaced with a rack-and-pinion design. The rack itself was forward mounted with provided for greater steering precision. A high-effort booster was also included for better directional control at high driving speeds. The normal steering ratio for the C4 Corvette was a constant 15.5:1, which was considered quite tight/fast for an American car. A tilt/telescoping steering wheel was also made standard.

As with previous generations of Corvette, a High Performance Handling Package (Z51) was introduced for the C4 Corvette. This package included heavy duty shocks and lower control-arm bushings, upgraded front and rear springs and stabilizer bars, plus a tighter 13.0:1 quick-ratio steering system. The Z51 package also included optional “gymkhana” suspension components that stiffened the ride to a point where it was too harsh for normal road use but would permit the car to corner carrying a lateral force of 0.95g, the highest ever recorded by an American production car and higher than most European exotics.

Continuing along the path of improved handling, the Corvette was originally intended to include 16-inch wheels and Pirelli’s P7 performance tires, which were considered “state of the art” at that time. However, the production C4 came fitted with Goodyear Eagle VR50 tires, which were specifically designed by Goodyear for the new Corvette. These tires were specifically sized at P255/50VR-16. Specifically classified as “V-rated” tires, they were designed to withstand a maximum speed of over 130 miles per hour. These tires were evolved from Goodyear’s Formula 1 and Indy-car rain-tire program. The intent was to develop a tire that would shed water more effectively, thereby reducing the risk of hydroplaning, which was known to be an issue for wide, low profile tires. The tread patterns for these tires were most notable for their “gatorback” tread pattern.

The new tires were to be mounted on cast-alloy wheels. For one of the first times ever in automotive history, Corvette introduced “unidirectional” wheels to the design of the C4. Unidirectional wheels are specifically designed to include radial fins that draw in air which aids in cooling the braking system when the vehicle is moving forward. While this design provides longer brake life, it also requires specific left and right wheels. For the C4, the wheels selected were to be 8.5 inches wide in front and 9.5 inches in the rear, which meant none of the wheels were interchangeable.

The braking system was to be a blend of old and new. As before, the Corvette utilized large, 11.5-inch-diameter, aluminum, ventilated rotors at each wheel. Coupled to these was a new brake lining created by Girlock (an offshoot of the British Girling company). These semi-metallic brake pads included audible wear indicators, and were intended to be a quick change design – meaning that they could be removed from the calipers and replaced within minimal effort.

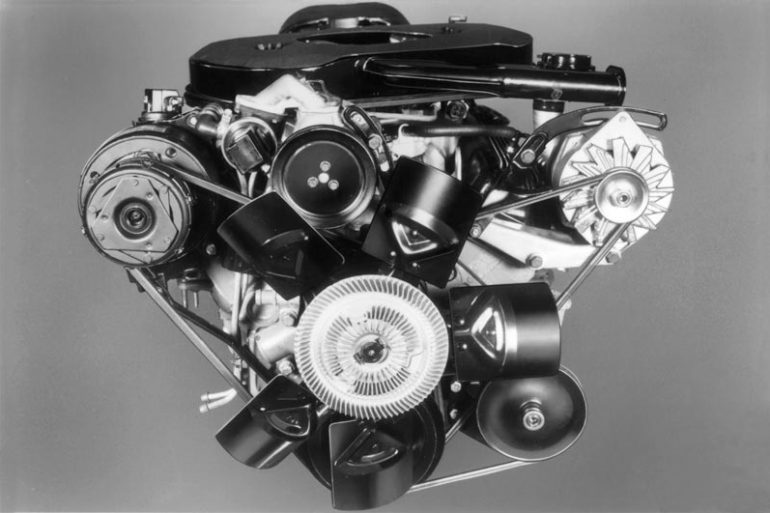

One of the few carryovers from the C3 Corvette was the 5.7-liter (350 cubic inch) small-block V-8 engine with twin throttle-body electronic fuel injection and “CrossFire” manifolding with dual ram-air intakes.

Though still carrying the L83 designation, the engine produced an additional five horsepower – producing a total of 205hp at 4,300 rpm – and five extra foot pounds of torque – 290 at 2,800 rpm – all via a more efficient radiator fan and accessory drive.

The engine sported a flat-top die-cast magnesium air cleaner that was developed by Palmer’s team. Separate vacuum-modulated doors molded into the underside of the hood regulated incoming air flow. These air ducts mated with the air cleaner assembly when the large, “clamshell” hood was closed. A single air intake below the front bumper fed air into the under hood ducts, making the first of the C4 Corvette’s a “bottom breather” like the C3 “Shark” before it. To enhance it’s internal styling, John Cafaro, a junior member of Palmer’s “Studio Three” team, developed a color scheme that would enhance the appearance of the engine compartment. Most components within the engine compartment were color-coordinated, including the engine block and fan casings which were painted black, an air cleaner which was manufactured in die-cast magnesium alloy and even an appropriately styled AC-Delco battery which was custom produced in black and silver.

To that end, Cafaro and the “Studio Three” team addressed every possible detail, leaving no design element untouched. The special styling that carried across the design of the car included special customizations to the engine compartment that extended far beyond the paint scheme. The wiring within and throughout the car was produced with a level of detail and attention that had not been seen since the days of the Cadillac V16s. Other, smaller aesthetic details found their way from the design team to the actual car as well including such things as a specially designed oil dipstick handle.

Another blending of “the old with the new” was the re-introduction of a four-speed manual gearbox as the Corvette’s standard transmission. However, this new four-speed was unlike any transmission that had come before it. Designated the “4+3 Overdrive”, it was essentially a standard four speed transmission with a second set of three planetary gears attached at the rear.

This second set of gears would be controlled by the engine’s Computer Command Control electronics. When signaled, the auxiliary gear set engaged through a hydraulic clutch to provide a step-down or overdrive reduction of 0.67:1 in each of the top three gears. The intended result of this “step-down” was to improve partial-throttle fuel economy. For best performance, the “+3 Overdrive” was electronically disengaged at wide throttle openings, though this option would be later supplemented by a console-mounted manual override switch. Standard final drive gearing was 3.07:1 with option 3.31:1 gearing available for better standing-start performance.

It took the better part of five years to completely integrate all of the components that were developed between Palmer and McLellan into a cohesive, complete car that could readily go to commercial production. In the early spring of 1983, the new C4 Corvette was publicly unveiled for the first time. To the relief of General Motors executives, engineers and designers, the Corvette was met with unbridled enthusiasm by both fans and critics alike. The C4 was still a Corvette in appearance, although it was also an entirely new car that was bolstered with a level of high technology unlike anything that had been seen prior to it’s unveiling.

The C4 Corvette Model Timeline

1984 Corvette

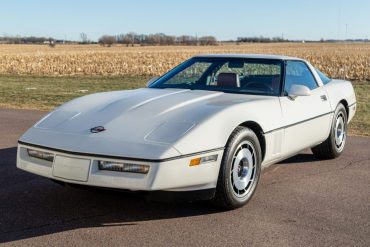

The C4 generation Corvette cars should have begun selling in 1983, but they didn’t. Development and quality control issues prevented the introduction of the C4 Corvette until March of 1983, 6 months beyond the typical September new model introduction. In short, no 1983 Corvettes were ever offered to the public; the C4 was introduced as a 1984 model. As GM was still struggling with ever-increasing emissions regulations, the focus for early C4 Corvettes was on handling and chassis dynamics. Despite the delay, the C4 was an instant success, selling a total of 51,547 units in its first year. Reviewers appreciated the car's modern amenities, such as the instrument cluster with a digital LCD and the 16-inch 50-series Goodyear tires. The 1984 model also featured the small-block L83 V8 engine from the 1982 Corvette, which included the short-lived throttle-body Cross-Fire fuel injection. It put out 205 horsepower and 290 foot-pounds of torque. Due to a lack of support for the fuel injection, some modern car collectors are critical of the 1984 Corvette.

1985 - 1986 Corvette

Chevy continued to improve the C4 Corvette over the years. In 1985, the controversial L83 V8 engine was replaced with a more powerful and fuel-efficient L98 featuring the tuned-point fuel injection, with a healthy 230 horsepower and 330 foot-pounds of torque. Top speed was 150 mph. The suspension for the 1985 C4 was also softened by 25 percent and 39,729 units were produced.

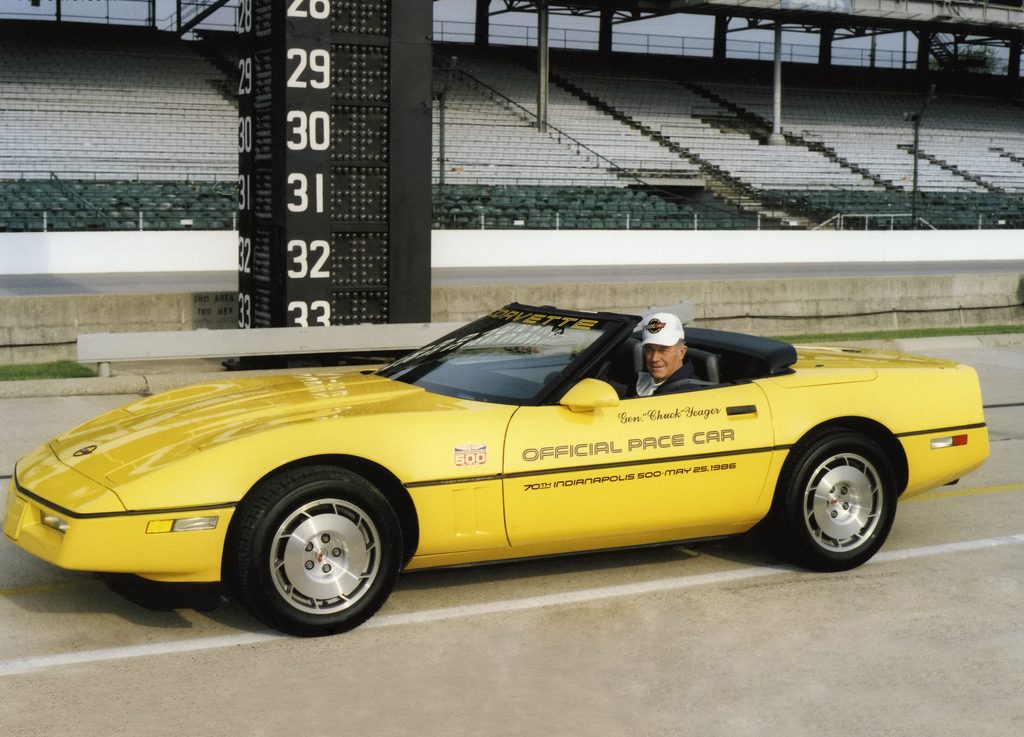

1986 saw the return of the Corvette convertible for the first time in 11 years. Based on the yellow C4 convertible pace car used in the 1986 Indy 500, the Corvette convertible sold for an extra $6,000 and featured an Indy 500 pace car plaque. 1986 was also the year the Corvette got the Pass Key I passive anti-theft system. This system only unlocked the car doors if it detected one of 15 electrical resistance values produced by a special pellet in the car keys. The 1986 Corvette also introduced antilock brakes, electronic climate control and a third brake light. In 1986, a total of 35,109 C4s were sold.

1987 - 1989 Corvette

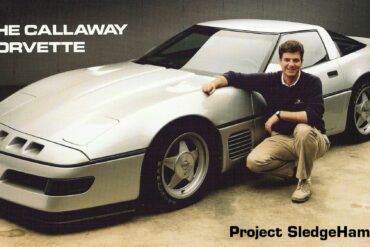

In 1987, the Corvette C4's engine gained roller hydraulic lifters to boost its horsepower to 240. Customers who wanted to supercharge their engine could buy the $19,999 B2K twin-turbo engine conversion, supplied by Callaway Cars in partnership with Chevrolet, to increase the engine's horsepower to 345 and its torque to 465 foot-pounds. The result was one of the fastest cars of its time. In 1987, 30,632 C4s were sold.

The 1988 model year saw the release of the 35th Anniversary Edition Corvette, also known as the Triple White Corvette. This car is all-white, including its wheels and interior, and features a special engine and removable black top. Of the 2,050 Anniversary Edition Corvettes produced, only 180 have manual transmissions.

C4s also underwent suspension changes and a new wheel design in 1988. The emergency brake was also moved toward the rear of the car for easier entering and exiting. In 1988, 22,789 C4s were sold. 1988 was the last year the Doug Nash 4+3 transmission was available. This transmission combined a four-speed manual with an automatic overdrive on three gears. The ZF six-speed manual replaced the 4+3 in 1989. In 1989, 26,412 C4s were sold at a base price of $32,045.

1990 - 1993 Corvette

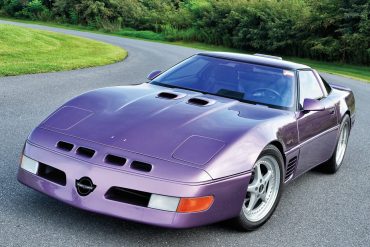

With the help of Group Lotus, a UK-based engineering consultant, Chevrolet sought to produce the fastest production car in the world. The result was the ZR1, a Chevrolet Corvette C4 option package released in 1990, which broke the record for the 24-hour, 5,000-mile land speed, achieving speeds of 175 mph. The C4 ZR1 cost $58,995, making it by far the most expensive Corvette up to that point. However, the Chevrolet Corvette ZR1 sold well. Over 3,000 people bought it in the first year, and some paid over $100,000 for it.

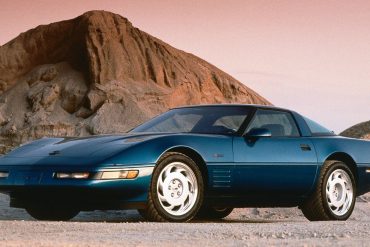

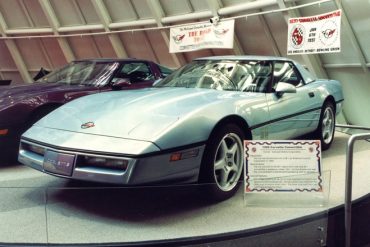

The regular C4 also saw refinements in 1990: a drivers-side airbag and an optional 200-watt six-speaker sound system. In all, 23,646 C4s were sold in 1990. 1991 saw minor tweaks. The cost for a C4 rose to $33,005, and the exterior had some restyling. 20,639 C4s were sold. 1992 saw much larger changes. Most notably, the LT1 V8 replaced the L98, delivering 300 horsepower and 330 foot-pounds of torque, plus the short-lived optically triggered Optispark ignition system. 1992 also witnessed the one-millionth Corvette ever made. The price for a standard C4 rose to $33,635, and 20,479 of the cars were sold.

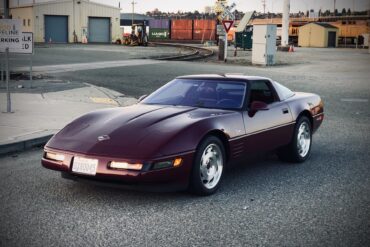

In 1993, Lotus helped Chevrolet modify the C4's valvetrain, exhaust system and aluminum cylinder heads to improve power and torque. Passive keyless entry was added to all models as well, and an exhaust re-circulation system was introduced to make controlling emissions easier. This model year also saw the release of the 40th Anniversary C4, featuring ruby metallic paint and ruby leather seats. At a base price of $34,595, a total of 21,590 C4s were sold in 1993.

1994 - 1996 Corvette

1994 didn't see many changes. The base price rose to $36,185, a passenger airbag was added, and the LT1 engine received a mass airflow sequential fuel injection. In all, 23,330 Chevrolet Corvette C4s were sold. 1995 was similarly uneventful. It saw a second-generation Optispark ignition system and some exterior restyling. The car cost $36,785, and 20,742 were sold. In 1996, there was an optional LT4 engine was produced, delivering 330 horsepower. Plus, an optional real-time damping system was available, which monitored the road to reduce vibrations. The 1996 C4 also debuted Chevrolet's OBD II onboard diagnostics system.

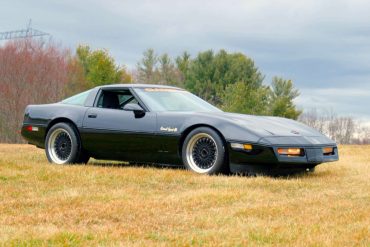

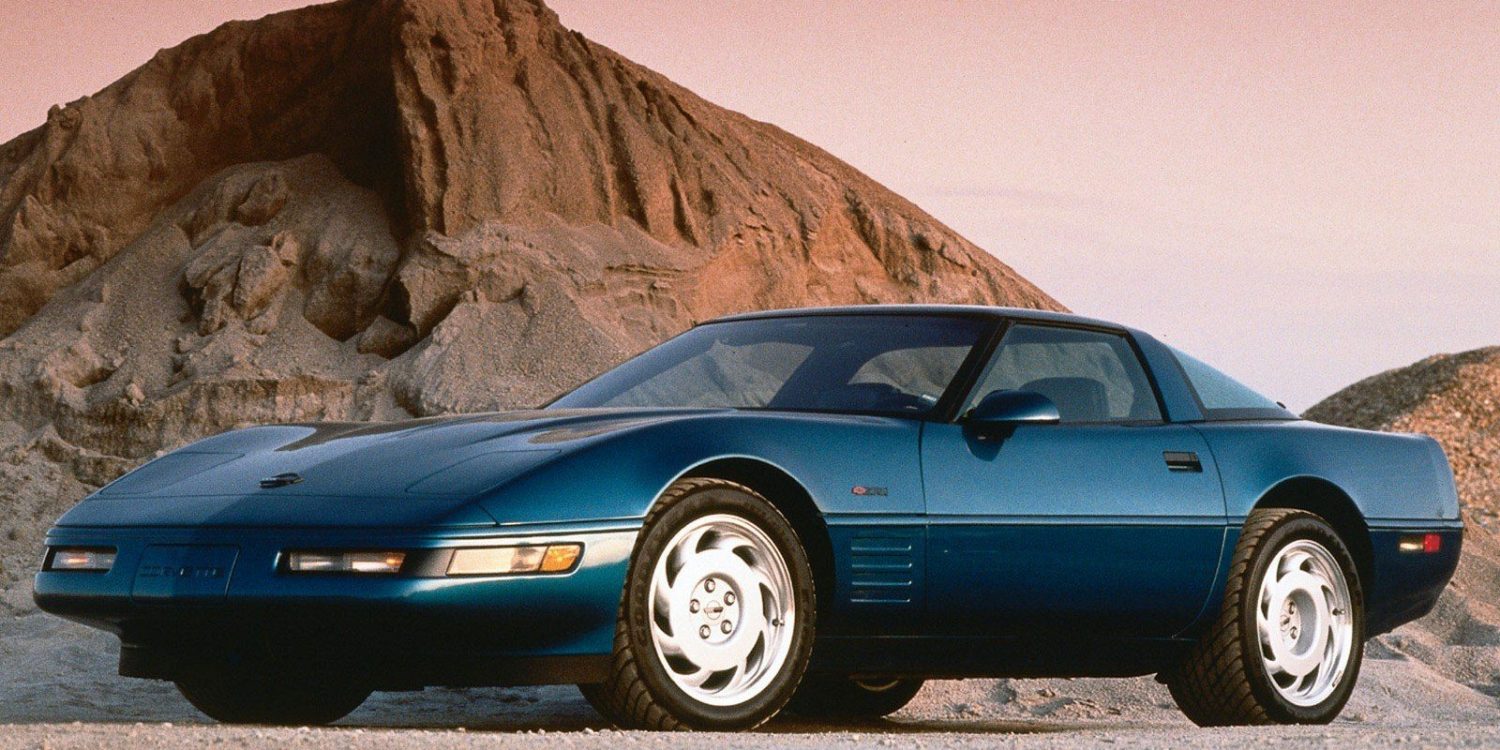

In addition, Chevrolet released the Chevrolet Corvette Grand Sport to celebrate the end of this generation of Corvettes. Inspired by the Grand Sport of 1963, this Grand Sport came exclusively in Admiral Blue with a white stripe and featured black wheels and bold red hash marks on the driver's side wheel arch. Only 1,000 Grand Sports were made: 190 convertibles and 810 coupes. 1996 also saw the release of a Collector's Edition Corvette, featuring silver wheels and a Sebring Silver paint job. 5,412 of these cars were built: 1,381 convertibles and 4,031 coupes. In all, 21,536 C4s were sold in 1996 at a base price of $37,225.

The C4 Corvette Market - Sales & Auctions

C4 Corvettes for Sale. This is our C4 Corvette auction and sales area. We share upcoming auctions, recent auction results, cool C4 Corvettes we find for sale and commentary on the current market for C4 Corvettes.

The C4 Corvette Newsfeed

Awesome restorations, sacrilege restomods, cool C4 Corvettes at auction or for sale, this is your newsfeed for all things C4 Corvette.

C4 Corvette Technical Research

Production and sales numbers, order guides and sales brochures, we have more C4 Corvette research than you could ever want.

C4 Production

Ever wanted to know just how many C4 Corvettes were made? We have you covered.

C4 Pricing

Looking to decode your C4 Corvette or find the options and pricing for reference. See them all below.