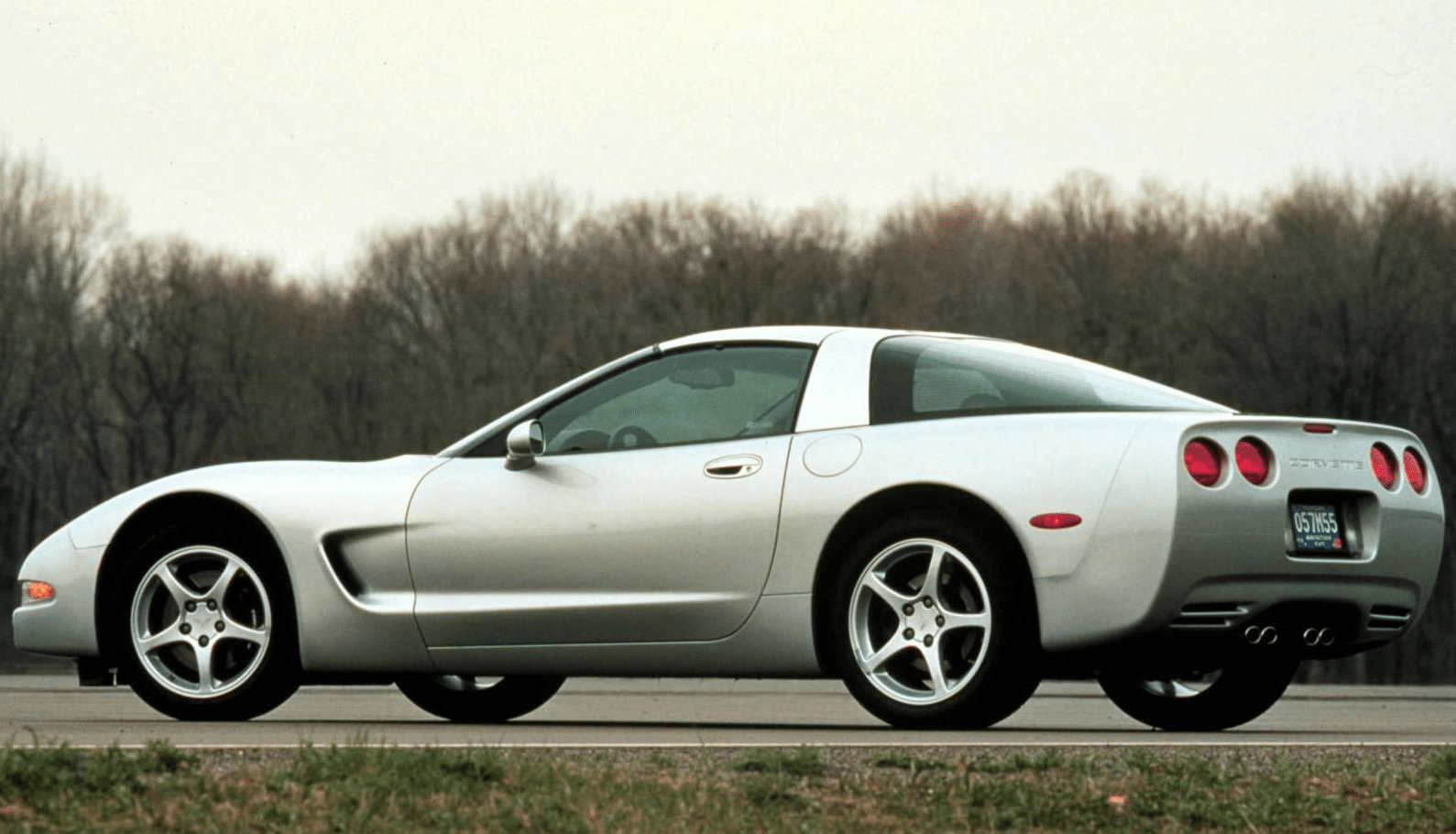

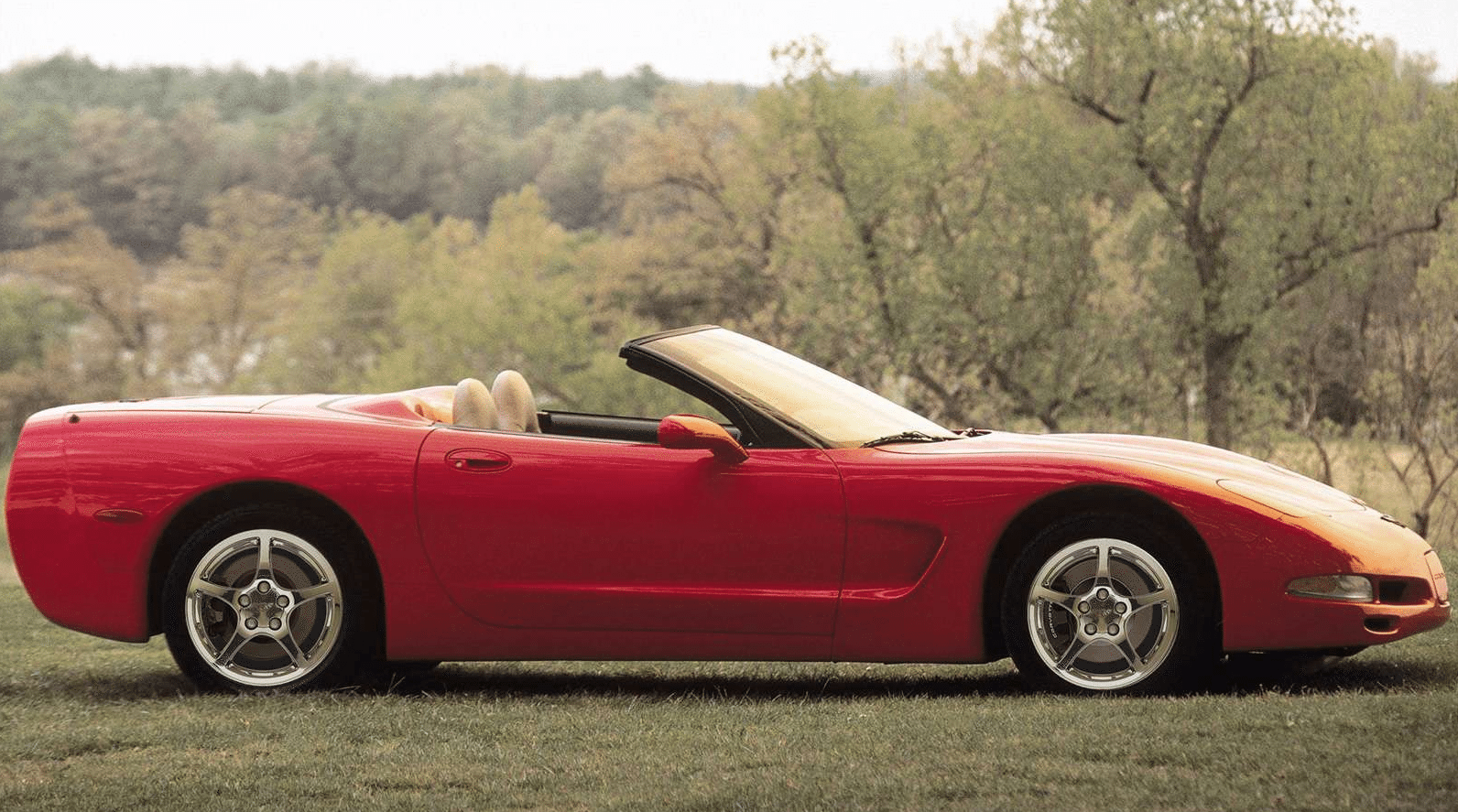

2000 Corvette – The Ultimate Guide

Since its inception in 1997, the C5 Corvette had proved to the world that it was not only a serious contender on the street but on the racetrack as well. The arrival of the new century – and the new millennium – did nothing to deter that opinion.

While the 2000 C5 Corvette underwent little physical modification from that of its predecessor, it did receive some limited design changes as well as some unique enhancements that continued to perpetuate the car’s popularity both on the track and at the dealership.

Corvette began the new millennium with continued momentum at the racetrack. While the C5-R had established itself as a contender at the racetrack during the 1999 racing season, Chevrolet decided to increase the cars capabilities by enhancing it for the 2000 season. To start, Chevrolet replaced the race car’s 6.0 liter engine with a 7.0 liter V-8, which resulted in a net increase of 20 horsepower for the 2000 C5-R. The car placed third and fourth in its class (10th and 11th overall) at the 24 Hours of LeMans in June, 2000.

In September of that same season, Corvette (and its drivers Ron Fellows and Andy Pilgrim) would gain its first victory during the American LeMans Series (ALMS) race in Ft. Worth Texas.

Production Corvettes did not receive any substantial mechanical changes for the 2000 model year, though a few enhancements were made. Perhaps the most notable of these involved the upgrades made to the Z51 Performance Handling Package. To start, the Z51 Package included larger stabilizer bars on both the front and rear of the car and the introduction of revised shock-absorbers damping. While these changes did not produce a notably stiffer ride, they did improve handling, especially in transient maneuvers, by increasing roll stiffness.

Most of the other mechanical improvements for the 2000 Corvette centered around drivability and ride stability as well. Engineering improvements were made to the Selective Real-Time Damping suspension. These changes largely involved the introduction of new or revised algorithms integrated with a re-designed (softer) jounce bumper for ride and handling improvements.

DID YOU KNOW: Production of a single C5 Corvette takes 55 hours from start to finish. However, this is actually 15 hours less than the production of the C4 Corvette. This is due in large part to the fact that the C5 Corvette actually had fewer mechanical components than the earlier Corvette

Additionally, improvements were also made to the manual-transmission shifter. The tension of the spring that located the shifter between the first-second gear gate and the fifth-sixth gate in the manual transmission was increased to provide a better sense of gear location and selection.

Still other mechanical improvements included improved windshield seals, the introduction of dual-zone climate control, and changes to the seat belts, seat materials and seat construction.

Cosmetically, there were virtually no changes made to the car design, although there were some minor improvements made to the detailing on the car.

Most significant of these changes was the modifications made to the five-spoke, standard aluminum wheels. The new wheels were now fully forged with a flow-formed rim for greater durability, even though the new wheels featured thinner spokes than its predecessors.

While the new “thin-spoke” design was standard, a polished version of the wheel was also made available to consumers under option RPO QF5 at an additional cost of $895.00. The popularity of this alternate polished wheel caused Chevrolet to announce in January, 2000 that a new, painted wheel from a different supplier would become standard to permit an increase in production of the polished wheel. This new standard wheel was similar in design, though it did feature slightly thicker spokes.

The proximity-based keyless entry system, which had proved to be perplexing to many consumers, was discontinued for 2000 in favor of a more conventional keyfob that utilized button controlled actuation. While the proximity controlled system had been around since its introduction in the 1993 Corvette, few consumers were saddened to see it replaced by this new, more conventional access-control system, which enabled drivers to lock and un-lock their cars with the press of a button.

As an added benefit of providing an easily usable keyless entry system, Chevrolet designers decided to eliminate the passenger side outside door lock, leaving the driver-side key cylinder as the only mechanical means of locking/unlocking the Corvette in the event of a dead battery.

The proximity-based keyless entry system, which had proved to be perplexing to many consumers, was discontinued for 2000 in favor of a more conventional keyfob that utilized button controlled actuation. While the proximity controlled system had been around since its introduction in the 1993 Corvette, few consumers were saddened to see it replaced by this new, more conventional access-control system, which enabled drivers to lock and un-lock their cars with the press of a button. As an added benefit of providing an easily usable keyless entry system, Chevrolet designers decided to eliminate the passenger side outside door lock, leaving the driver-side key cylinder as the only mechanical means of locking/unlocking the Corvette in the event of a dead battery.

RACING: After making its debut return to racing in 1999, the C5-R Corvette proved its mettle in the 2000 season by competing – and winning races – in the American LeMans Series. First, on September 2, 2000, the No. 3 Corvette Racing’s C5-R Corvette finished first in the GTS race class (and eighth overall) after qualifying/starting second and running a total of 116 laps. Next, on September 30, 2000, team Corvette Racing’s car No. 4 finished first in the GTS class (and 9th overall) after completing 358 laps at Road Atlanta. Car. No. 3 (also of Corvette Racing) finished 3rd in the GTS class (and 11th overall) at the same race.

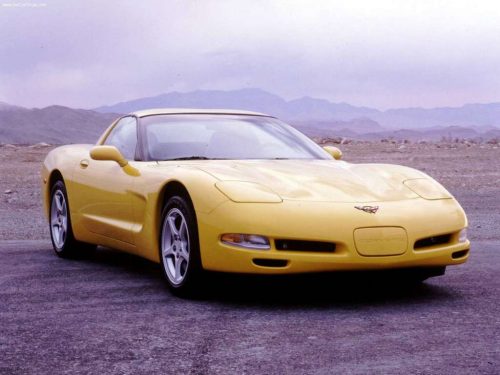

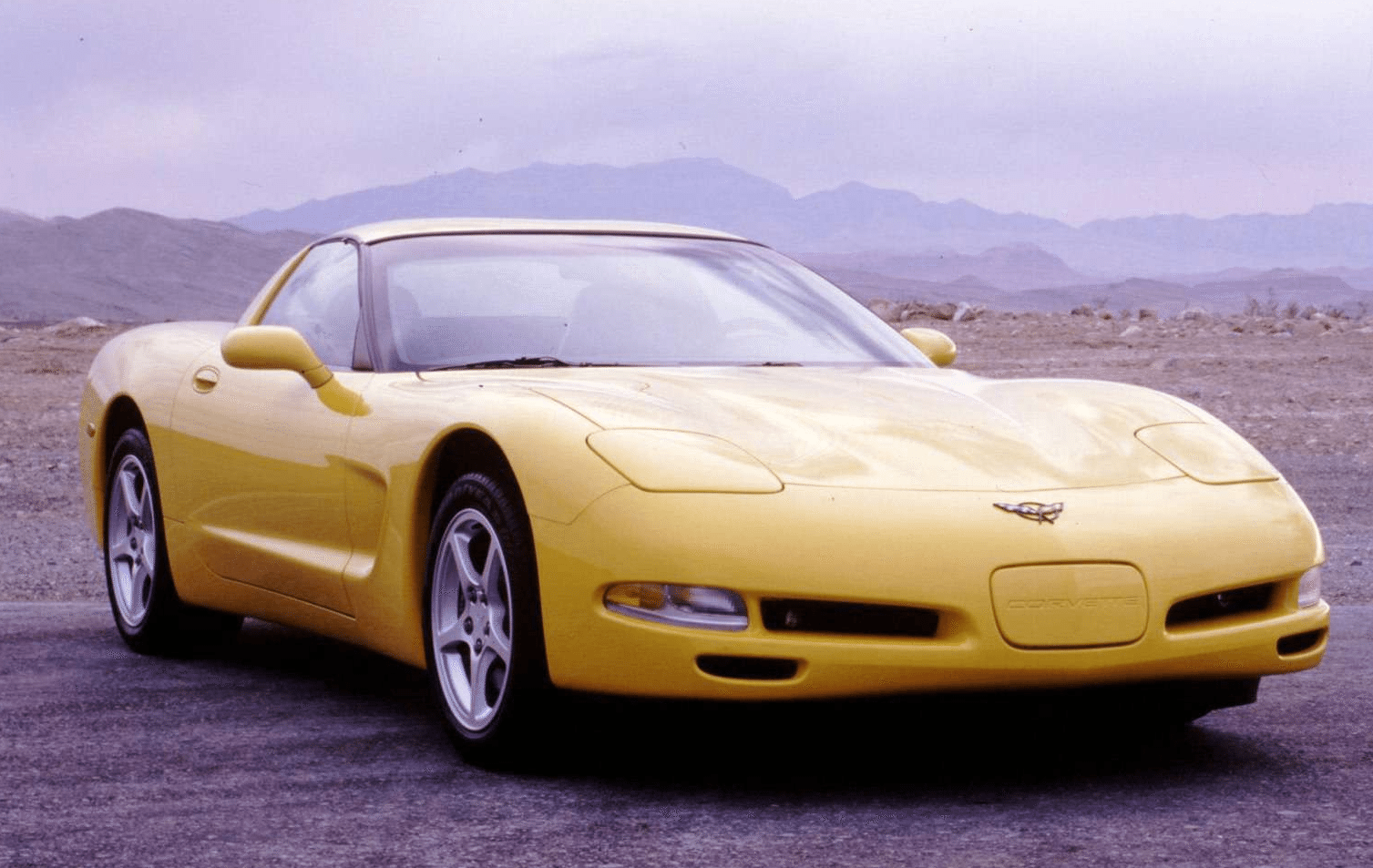

To commemorate the arrival of the new millennium, Chevrolet offered two new paint colors or the 2000 model year – Millennium Yellow and Dark Bowling Green Metallic. Much like the 1999’s Red Metallic exterior (which carried over into 2000), Millennium Yellow carried an additional cost of $500.00. The additional cost was because of the paint itself, but the result of the special equipment and process required for producing a tinted clear coat that added visual depth to the paint’s appearance.

Production Volumes

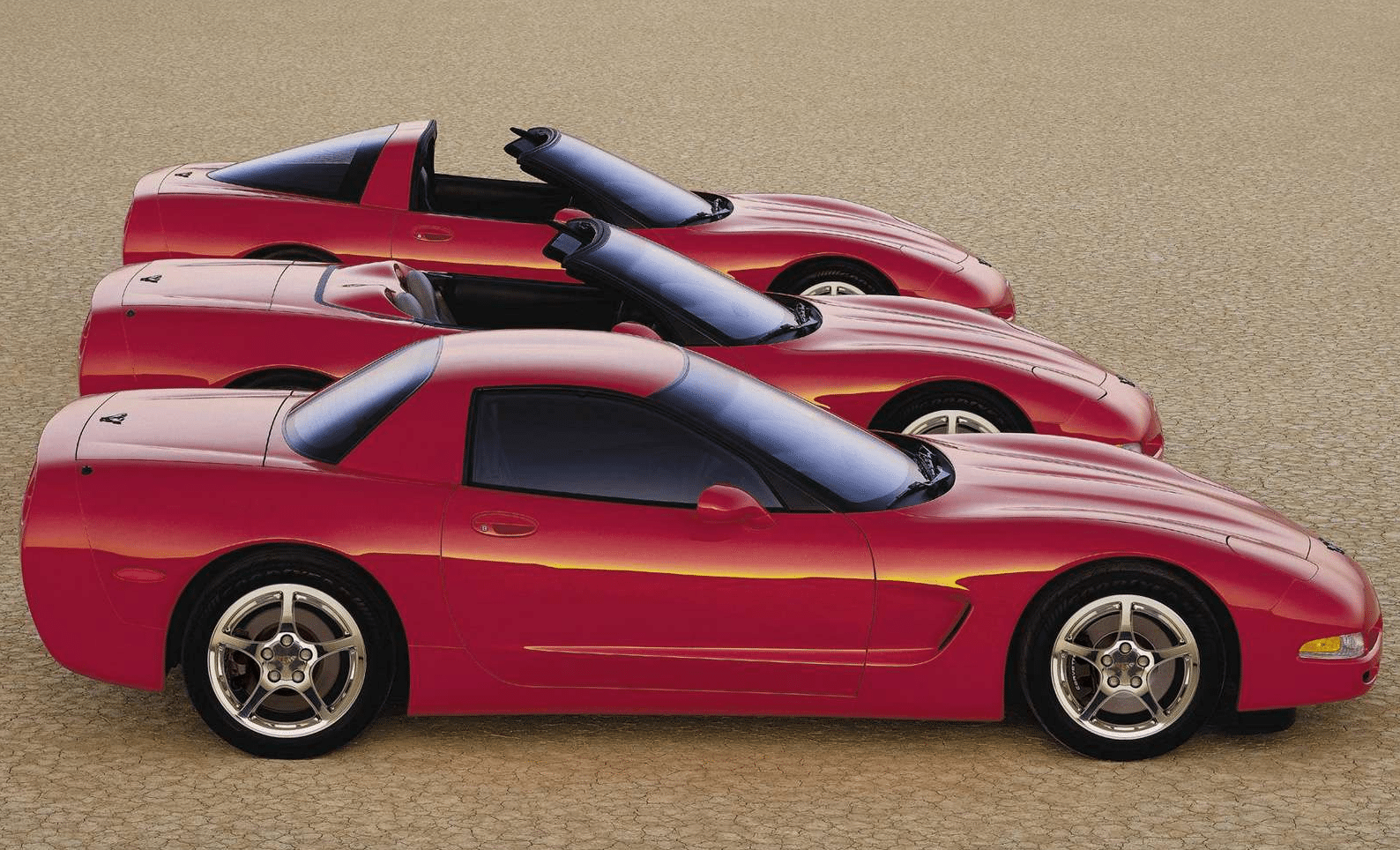

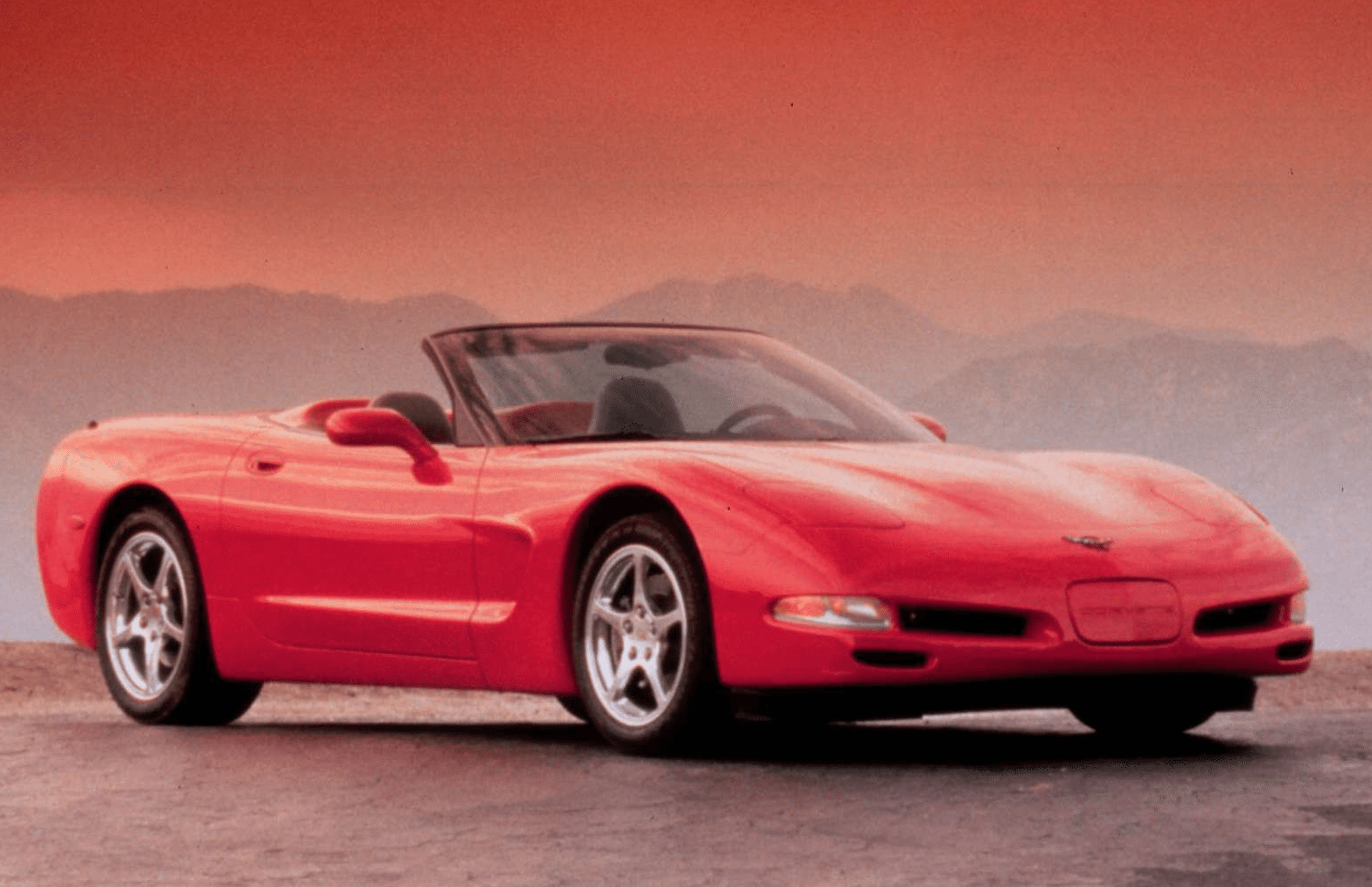

Prices for the Corvette increased only marginally for the 2000 model year. The Corvette Coupe was now priced at $39,280 and accounted for a total of 18,113 units sold that year. The convertible price was increased to $45,705 and accounted for 13,479 units that year. By comparison, the FRC was priced lowest at $38,705, but only accounted for 2,090 units that year. While the Coupe, Convertible, and FRC Hardtop (Fixed Roof Coupe) all returned for the 2000 model year, it would mark the last year for the FRC Coupe. While some consumers claimed that the short-lived run of the FRC Corvette was the direct result of poor sales figures, the reality of the decision was somewhat more complex. While the hardtop Corvette promised increased performance, it offered little real performance improvement over the base model coupe. Still, while the improved suspension, steering and handling did provide consumers a superior driving experience in some respects, General Motors was about to change the face of the Corvette market forever by introducing a variant of the hardtop coupe that would be more powerful than almost any Corvette that had come before it.

2000 Corvette Specifications & Performance

See the complete breakdown of technical specifications for the 2000 Corvette, including engine, suspension, brakes, body dimensions, and power. Read more: 2000 Corvette Specifications.

Engine, Transmission & Performance

No meaningful changes.

2000 Corvette Vehicle Identification Numbers (VIN)

The last six digits begin at 100001 and run thru 133610. The pilot and prototype cars were given a VIN number in this VIN series. Each Vehicle Identification Number (VIN) is unique to an individual car. For all 2000 Corvettes in the U.S. and Canada, the Vehicle Identification Number (VIN) was stamped on a plate on the inner vertical surface of the left windshield pillar visible through the windshield. Read more: 2000 Corvette VINs.

2000 Corvette Price & Options

Core Features & Factory Options

Chevrolet had three straight years of incredible new Corvette products, but the product planners took a well deserved break in 2000. A few changes this year, the “Wagon Wheel” wheels were replaced with a new 5 spoke design. These standard wheels could be optionally polished. The Magnesium wheel option was only $2000 this year. Dark Bowling Green Metallic and Millenium Yellow were added to the exterior color lineup, Millenium Yellow costing an extra $500. The Firethorn Red interior was replaced with Torch Red. The Performance Handling Package (RPO Z51; $350.00) was revised with increased diameter front and rear anti-roll bars and revised shock absorbers. The Passive Keyless Entry system was replaced by a Active Keyless Entry system.

Colors

Arctic White 1,979 (5.88%), Light Pewter Metallic 5,125 (15.22%), Sebring Silver Metallic 2,783 (8.26%), Navy Blue Metallic 2,254 (6.69%), Black 5,807 (17.24%), Torch Red 6,700 (19.89%), Millenium Yellow 3,578 (10.62%), Magnetic Red Metallic 2,941 (8.73%), Dark Bowling Green Metallic 1,663 (4.94%), Nassau Blue Metallic 851 (2.53%). All colors were available with the hardtop except codes Millenium Yellow, Dark Bowling Green Metallic, Navy Blue Metallic, Sebring Silver Metallic and Magnetic Red Metallic. The Hardtop was limited to a black interior. As you can see, Red, Black and White continued to be the powerhouse colors for the 2000 Corvette, like most previous years. Read more: 2000 Corvette colors

Pricing & Options

Base Corvette Coupe with 346 cu. in. 345 hp engine and four speed automatic transmission: $39,475

Base Corvette Convertible with 346 cu. in. 345 hp engine and four speed automatic transmission: $45,900

Base Corvette Hardtop with 346 cu. in. 345 hp engine and six speed manual transmission: $38,900

*New for the 2000 model year

| CODE | DESCRIPTION | QUANTITY | RETAIL PRICE |

| 1YY07 | Base Corvette Sport Coupe | 18,113 | $39,475.00 |

| 1YY37 | Base Corvette Hardtop | 2,090 | $38,900.00 |

| 1YY67 | Base Corvette Convertible | 13,479 | $45,900.00 |

| AAB | Memory Package | 26,595 | $150.00 |

| AG1 | Power Driver Seat (Hardtop) | 1,841 | $305.00 |

| AG2 | Power Passenger Seat (Coupe & Convertible) | 29,462 | $305.00 |

| AQ9 | Sport Seats (Coupe and Convertible) | 27,103 | $700.00 |

| AP9* | Parcel Net (Hardtop) | 938 | $15.00 |

| B34 | Floor Mats | 33,188 | $25.00 |

| B84 | Body Side Moldings | 18,773 | $75.00 |

| CC3 | Removable Roof Panel, Blue Tint (Coupe) | 6,280 | $650.00 |

| C2L | Dual Removable Roof Panels (Coupe) | 5,605 | $1,100.00 |

| CJ2 | Electronic Dual Zone Air Conditioning | 29,428 | $365.00 |

| D42 | Luggage Shade and Parcel Net (Coupe) | 15,689 | $50.00 |

| F45 | Selective Real Time Damping (Coupe & Convertible) | 6,724 | $1,695.00 |

| G92 | Performance Axle Ratio (3.15 ration) (automatic) | 14,090 | $100.00 |

| JL4 | Active Handling System | 22,668 | $500.00 |

| MN6 | 6-Speed Manual Transmission (Coupe & Convertible) | 13,320 | $815.00 |

| N37 | Telescopic Steering, Power (Coupe & Convertible) | 22,182 | $350.00 |

| N73 | Magnesium Wheels | 2,652 | $2,000.00 |

| QF5* | Polished Aluminum Wheels | 15,204 | $895.00 |

| T82 | Twilight Sentinal (Coupe & Convertible) | 23,508 | $60.00 |

| T96 | Fog Lamps | 31,992 | $69.00 |

| TR9 | Lighting Package (Hardtop only) | 1,527 | $95.00 |

| UN0 | Delco Stereo System with CD | 24,696 | $100.00 |

| UV6 | Head Up Display (HUD) | 26,482 | $375.00 |

| UZ6 | Bose Speaker Package (Hardtop) | 1,766 | $820.00 |

| U1S | Remote Compact 12-Disc Changer | 15,809 | $600.00 |

| V49 | Front License Plate Frame | 17,380 | $15.00 |

| YF5 | California Emissions | 3,628 | $0.00 |

| Z51 | Performance Handling Package | 7,775 | $350.00 |

| 79U* | Millennium Yellow Paint (Coupe & Convertible) | 3,578 | $500.00 |

| 86U | Magnetic Red Metallic Paint (Coupe & Convertible) | 2,941 | $500.00 |

Read more: 2000 Corvette pricing and factory options

2000 Corvette Gallery

See full 2000 C4 Corvette Image Gallery

2000 Corvette Videos

See more 2000 Corvette Videos

just puvetrchaed c 5