1974 Corvette – The Ultimate Guide

The arrival of the 1974 Chevy Corvette occurred during an abysmal period in automotive history. The period in question actually began in October, 1973 when OAPEC, (the Arab members of OPEC (the Organization of Petroleum Exporting Countries) plus Egypt, Syria, and Tunisia) proclaimed an oil embargo against the United States after the United States came to the aid of the Israelis during a military altercation between Egypt, Syria, and Israel.

While the actual embargo only lasted a few months (it ended in March, 1974, after OPEC received considerable pressure from NATO), the impact the embargo had on the automotive community was detrimental. Gas prices had soared, and massive fuel shortages had occurred, leaving motorists waiting in long lines at the pumps. In some instances, gasoline was actually rationed, especially in more densely populated areas. While the embargo was short-lived, it made automotive manufacturers seriously question the value that heavy, fuel-thirsty cars were bringing to the marketplace.

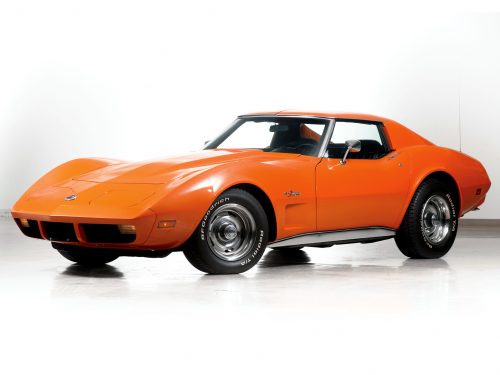

In many ways, the 1974 Corvette would represent the end of an era. Perhaps because of the embargo, and certainly a byproduct of it, The 1974 model would be the last year to be offered with an optional big-block 454 cubic inch V-8 engine.

Additionally, all future engines offered with the Corvette would only run on unleaded gasoline – a decision would come in conjunction with the industry-wide requirement to install catalytic converters in every 1975 (and later) model. For its own part, the 1974 Corvette required 91-octane leaded or low-lead fuel.

Lastly dual exhaust would give way to separate manifolds routed to a single catalytic converter, then onward to separate pipes and motors. In fact, the 1974 Corvette would be the last model year that would exclude the installation of catalytic converters.

DID YOU KNOW: RPO YJ8 Cast Aluminum Wheels appeared on early 1974 option lists, but records indicate that none were sold. Since RPO P02 Deluxe Wheel Covers were no longer available, there were no optional wheels or wheel-covers available for the 1974 Corvette

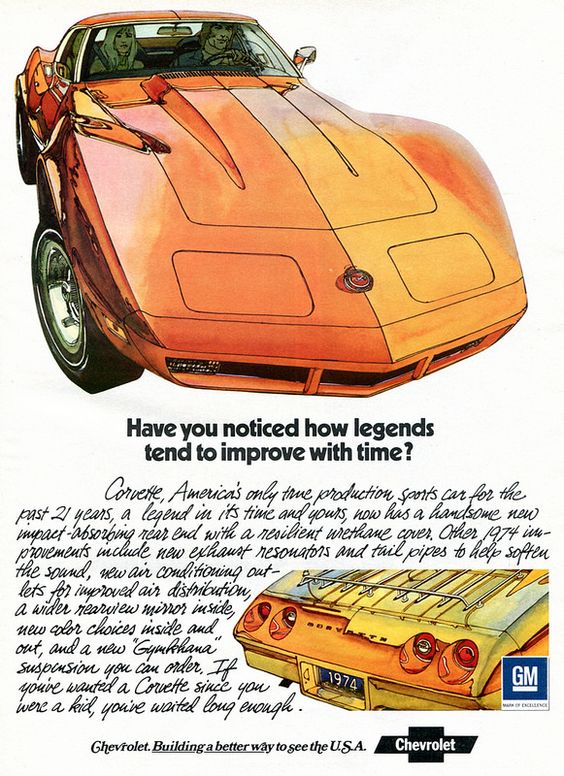

Cosmetically, the 1974 Corvette received a new body-color rear-end treatment that was made to comply with a new, Federally imposed five-mile-per-hour impact standard.

Sheathed in urethane like the 1973‘s front-bumper revision, the skin actually covered an aluminum impact bar that was mounted to the Corvette’s chassis by two telescopic brackets.

The new rear bumper conveyed a smoother, more integrated look, and while it tapered downward instead of upward (as the previous Kammtype rear end had done), it did not harm the car’s aerodynamics. The urethane plastic skin had built in recesses for the license plate and the taillights, and was actually assemble of two main sections that were divided by a vertical, center seam. This detail is unique to the 1974 model year and makes it easy to identify.

Turning to the interior, the 1974 Corvette received only minor enhancements. Perhaps the most notable improvement over the previous models was that the 1974 Coupe now featured an integrated shoulder belt/lap belt assembly for the first time. Shoulder belts remained optional in the convertible models, and if they were so equipped, continued to be a separate assembly from the lap belts. The locking mechanisms in the shoulder restraints also changed design from a pull-rate type (which would catch based on the amount of force applied to the belt) to a swinging-weight type that was activated by the car’s deceleration. Elsewhere in the interior, the stock inside rearview mirror increased in width from 8 to 10 inches. Mechanically, a handful of improvements were made to the car. The standard RPO ZQ3 engine’s output increased slightly from the previous model year to 195 horsepower.

The market’s growing preference for performance automatic transmissions resulted in a more durable Turbo Hydra-Matic. Designated by RPO M40, the transmission was no-cost upgrade to consumers and was installed in nearly two-thirds of all the Corvettes built that year.

The radiator was redesigned for more efficient cooling at low speeds. The power steering pump was made more durable via the use of magnets, which were installed to attract (and capture) debris in the power steering fluid. Downstream from the engine, resonators were added to the exhaust system, which enhanced the tone of the car during operation.

With the newly designed rear bumper in place, the exhaust pipes were re-routed to exit just below the bumper (instead of cut into the rear fascia assembly as before.) Lastly, the alarm activator was relocated from the rear of the car to the driver side front fender.

New for the 1974 Corvette was one of the most bargain-priced performance packages of all-time. The Gymkhana Suspension Package (RPO FE7) cost a mere seven dollars, featured a higher-rate spring assembly and firmer, specially calibrated shocks. This setup – which had been introduced and used since the mid-Sixties as part of Chevy’s popular F41 Suspension Package – provided much improved handling on the 1974 Corvettes that were so equipped.

The F41 itself, which had begun with the Z06 racing option back in 1963, was still available as part of RPO Z07, and included the aforementioned suspension setup as well as heavy-duty brakes.

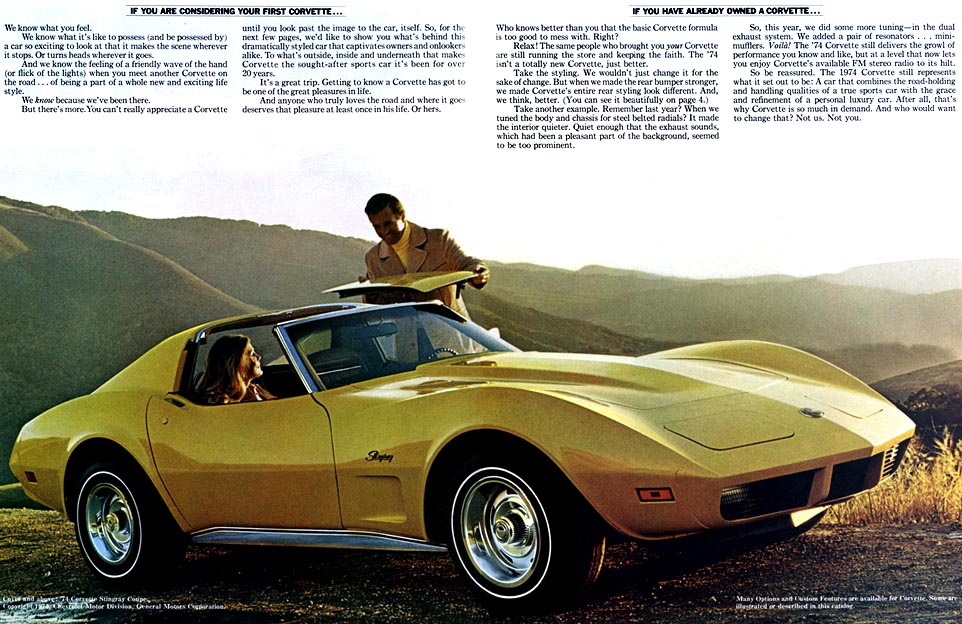

Given the performance constraints placed before it by Federal Emission Regulations, oil embargos, and a struggling economy, the 1974 Corvette still presented drivers with a respectable level of acceleration and performance. While it was hard to compare the 1974 Corvette to its slightly older, big-block brothers and sisters, its numbers spoke for themselves.

When equipped with the 250 brake horsepower L82 engine, the ’74 Corvette could accelerate from 0 to 60 miles per hour in approximately 7.5 seconds and reach a top speed of 125 miles per hour while still averaging about 14-15 miles per gallon. Moreover, what it lacked in outright performance it made up for in luxury.

Production Volumes

The 1974 Corvette would become widely recognized as a very refined, grand touring car with plenty of creature comforts. The 1974 Corvette defined industry standards by having a near-record sales year. In total, 37,502 Corvettes were sold – 32,028 coupes at a base price of $6,001.50, and a mere 5,474 convertibles at a base price of $5,765.50.

1974 Corvette Specifications & Performance

See the complete breakdown of technical specifications for the 1974 Corvette, including engine, suspension, brakes, body dimensions, and power. Read more: 1974 Corvette Specifications.

Engine & Transmission

Engine specifications plate for 454 cubic-inch 270 horsepower engine (RPO LS4, $250; Qty: 3,494 9.32%). Below: 350 cubic inch RPO L82 250 horsepower engine ($299.00; Qty: 6,690 17.84%). The base 350 cubic inch engine was rated at 195 horsepower. 1974 would be the last year the Corvette was available with a big-block V8, and it also would be the last year of genuine dual exhaust. These were the result of the forced switch to unleaded fuel as well as the widespread use of catalytic converters.

Performance

0 – 60 mph was a poultry 8.9 seconds in 350ci/250hp guise and the quarter mile took 15.6 seconds. This wasn’t the fun performance era by any stretch of the imagination. See more performance data.

1974 Corvette Vehicle Identification Numbers (VIN)

The last six digits begin at 400001 and run through 437502, accounting for 37,502 Corvette Coupes/Convertibles built in 1974. Each Vehicle Identification Number (VIN) is unique to an individual car. For all 1974 Corvettes, the location of the Vehicle Identification Number (VIN) is stamped on a plate attached to the left front body hinge pillar. Read more: 1974 Corvette VINs.

1974 Corvette Price & Options

Core Features & Factory Options

Regulations in 1973 required a 2.5 MPH bumper, which resulted in the body colored front bumper that also contributed to the new style of the Corvette, though that year’s model used a chrome bumper in the back. Regulations pushed the bumper requirement up to 5 MPH for 1974, resulting in the body colored rear bumper, which fit better with the front, anyway. For 1974, the back bumper consisted of two pieces and had a visible seam in the middle. Fortunately this would be fixed the following year. Elsewhere, the styling of the car was largely exactly the same as it had been in 1973.

Colors

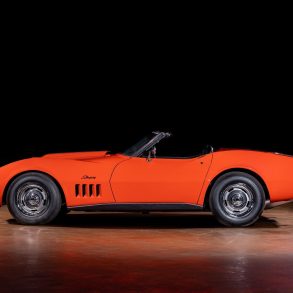

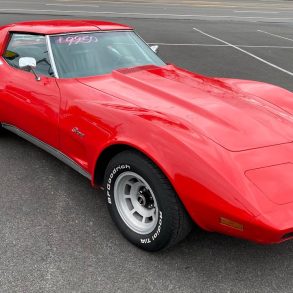

Exterior colors for the 1974 model year were Classic White, Silver Mist, Corvette Gray, Corvette Medium Blue, Dark Green, Bright Yellow, Dark Brown, Medium Red, Mille Miglia Red and Corvette Orange. More 1974 color details here.

Pricing & Options

The Base Corvette Coupe with 350 cu. in. 195 hp engine and wide ratio four speed manual transmission was $6,001.50 while the Base Corvette Convertible with 350 cu. in. 195 hp engine and wide ratio four speed manual transmission started at $5,765.00.

| CODE: | DESCRIPTION: | QUANTITY: | RETAIL PRICE: |

| 1YZ37 | Base Corvette Sport Coupe | 32,028 | $6,001.50 |

| 1YZ67 | Base Corvette Convertible | 5,474 | $5,765.50 |

| — | Custom Interior Trim | 19,959 | $154.00 |

| A31 | Power Windows | 23,940 | $86.00 |

| A85 | Custom Shoulder Belts (std with coupe) | 618 | $41.00 |

| C07 | Auxiliary Hardtop (for convertible) | 2,612 | $267.00 |

| C08 | Vinyl Covered Auxiliary Hardtop | 367 | $329.00 |

| C50 | Rear Window Defogger | 9,322 | $43.00 |

| C60 | Air Conditioning | 29,397 | $467.00 |

| FE7 | Gymkhana Suspension | 1,905 | $7.00 |

| — | Optional Rear Axle Ratios | 1,219 | $12.00 |

| J50 | Power Brakes | 33,306 | $49.00 |

| LS4 | 454ci, 270hp Engine | 3,494 | $250.00 |

| L82 | 350ci, 250hp Engine | 6,690 | $299.00 |

| M21 | 4-Speed Manual Transmission, close-ratio | 3,494 | $0.00 |

| M40 | Turbo-Hydro-matic Automatic Transmission | 25,146 | $0.00 |

| N37 | Tilt-Telescopic Steering Column | 27,700 | $82.00 |

| N41 | Power Steering | 35,944 | $117.00 |

| QRM | White Stripe Steel Belted Tires, GR70x15 | 9,140 | $32.00 |

| QRZ | White Letter Steel Belted Tires, GR70x15 | 24,102 | $45.00 |

| U05 | Dual Horns | 5,258 | $4.00 |

| U58 | AM-FM Radio, Stereo | 19,581 | $276.00 |

| U69 | AM-FM Radio | 17,374 | $173.00 |

| UA1 | Heavy Duty Battery (std with LS4) | 9,169 | $15.00 |

| UF1 | Map Light (on rearview mirror) | 16,101 | $5.00 |

| YF5 | California Emission Test | — | $20.00 |

| Z07 | Off Road Suspension and Brake Package | 47 | $400.00 |

Read more: 1974 Corvette pricing and factory options.

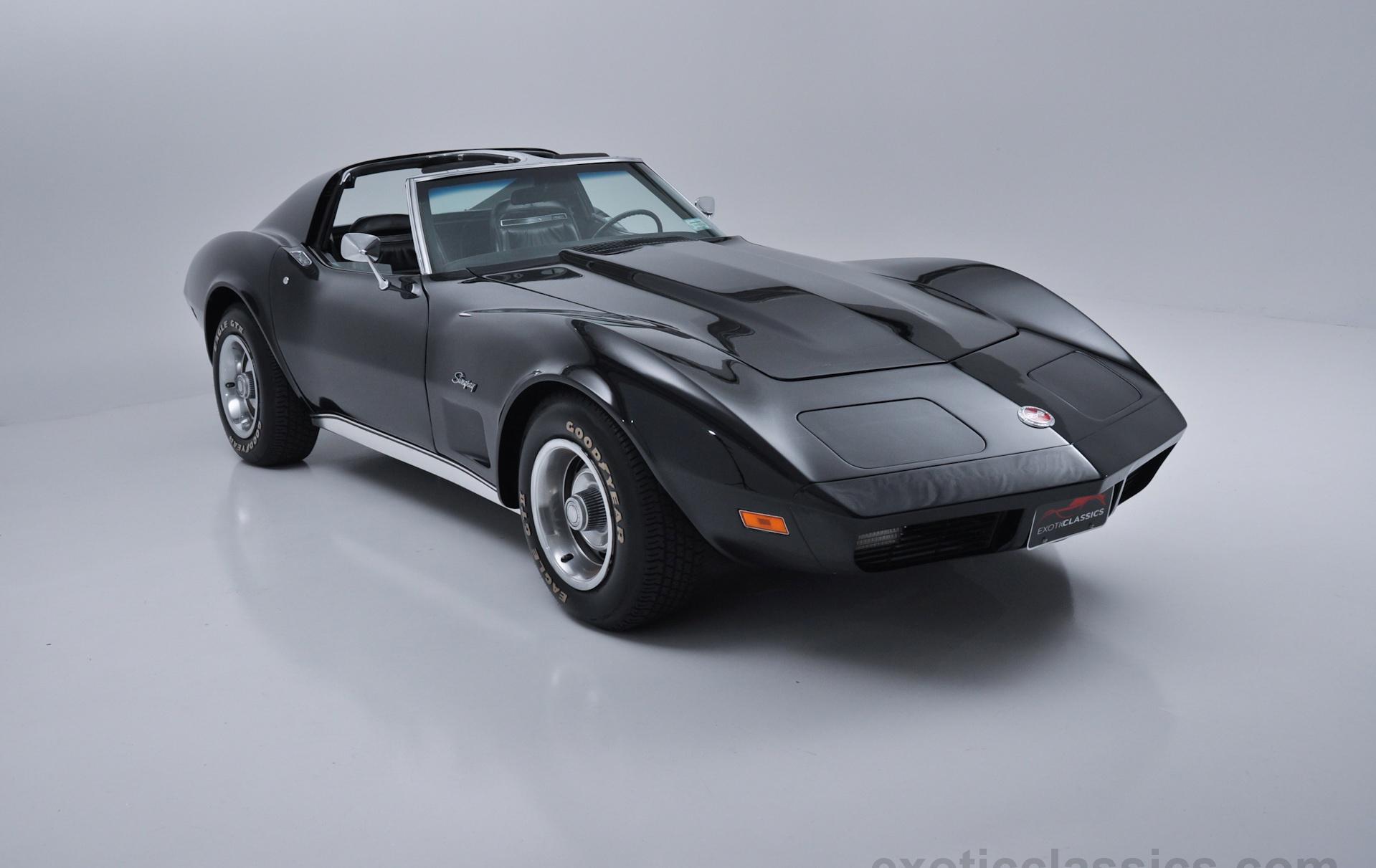

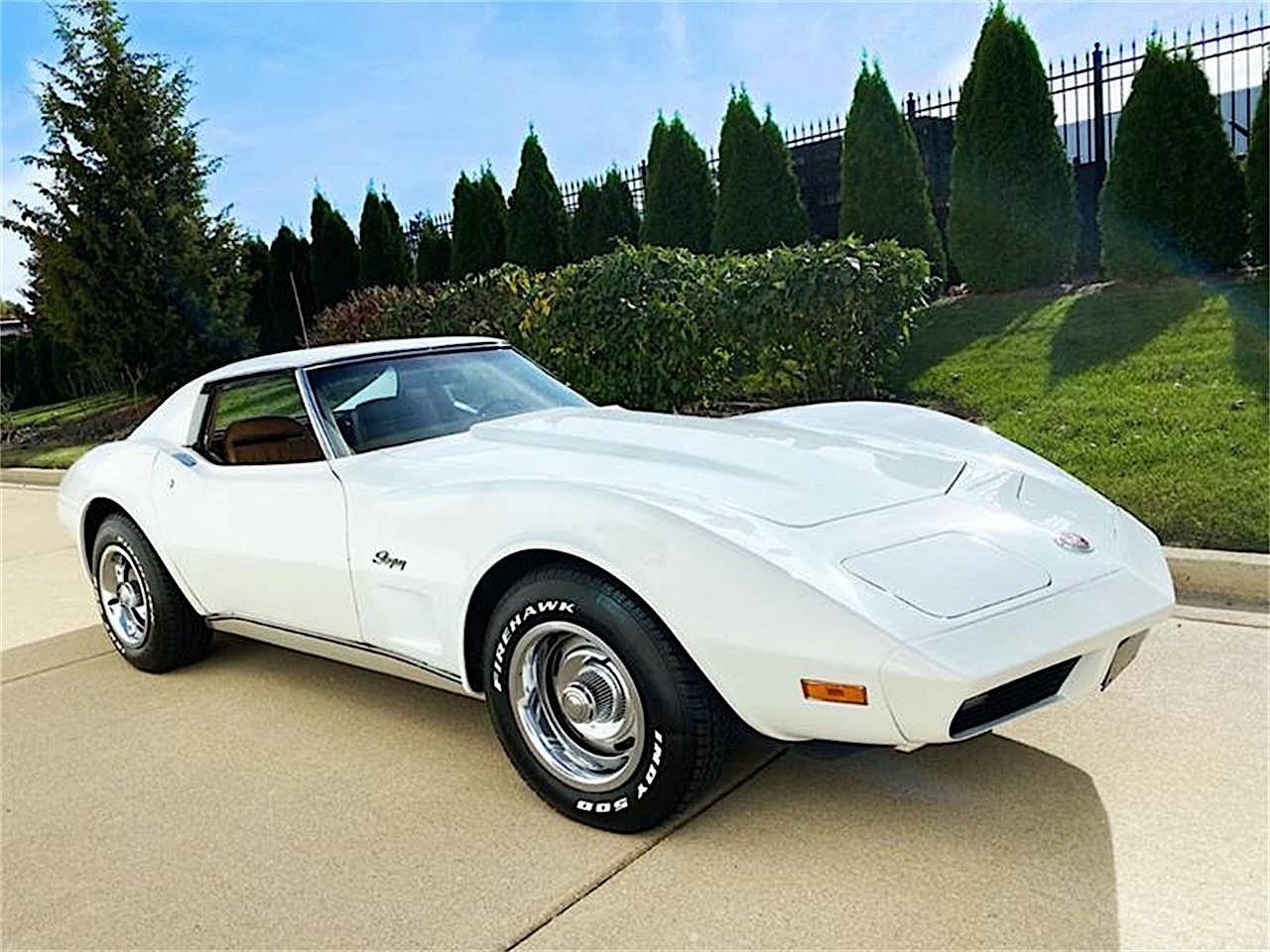

1974 Corvette Gallery

1974 completed what was started in 1973; this time the rear chrome bumpers were gone, also to accommodate new safety regulations. Corvette stylists had done chrome better than anyone, as a glance at any of the C1 Corvettes would attest. The Corvette bumper solution was far better than anything else on the road at the time. See full 1974 Corvette Image Gallery

In referring to the later 1975 exhaust system, the phrase “a single catalytic converter, then onward to separate pipes and motors.” probably was intended to read “…separate pipes and mufflers.”

Under capacity reference fuel, I believe this is oil capacity. I tried putting 4 gal. in my gas tank only to run out at the end of my driveway. : (

Fuel Capacity (gallons): 4.0 for 350ci. engines (capacity of crankcase less filter – refill)

5.0 for 454ci engines (capacity of crankcase less filter – refill)

I am looking for a original manual for a 1974 Stingray Corvette