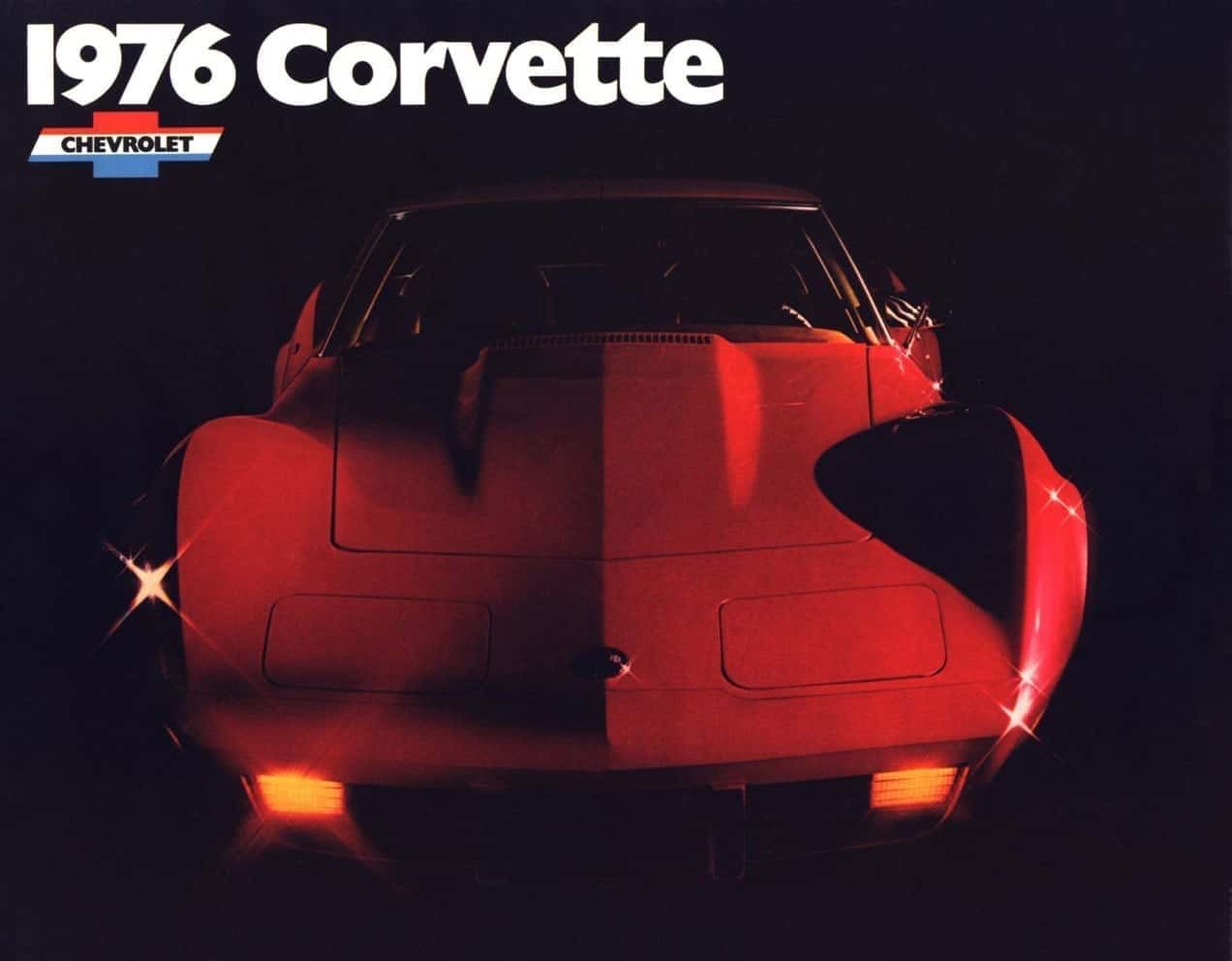

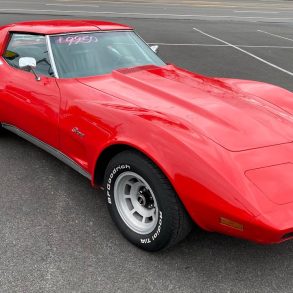

1976 Corvette – The Ultimate Guide

By 1976, the United States economy was on the mend from the 1973–1975 global economic recession. The recession, which had been caused in part by the 1973 oil crisis, had caused gas prices to soar which, in turn, had made automotive manufacturers begin re-evaluating the types of vehicles they were manufacturing.

It had led to the end of the big-block engine era for Chevrolet, and had further influenced the decision being made by automotive manufacturers everywhere to increase fuel economy at all costs – even if it meant a loss in horsepower as a result. However bad the prognosis had looked just a year earlier, 1976 had seen President Jimmy Carter come into office and with him, an eventual economic stimulus package that would re-strengthen a diminished economy.

Despite the economic hardships felt around the world, the 1976 Stingray had arrived on the heels of one of Corvette’s most successful sales years ever. The commercial success of the 1975 Corvette coupe (but not the convertible) had strengthened Chevrolet’s resolve to do away with the roadster option and focus solely on producing the best edition of their popular sports car possible. It was a gamble that would prove to pay off.

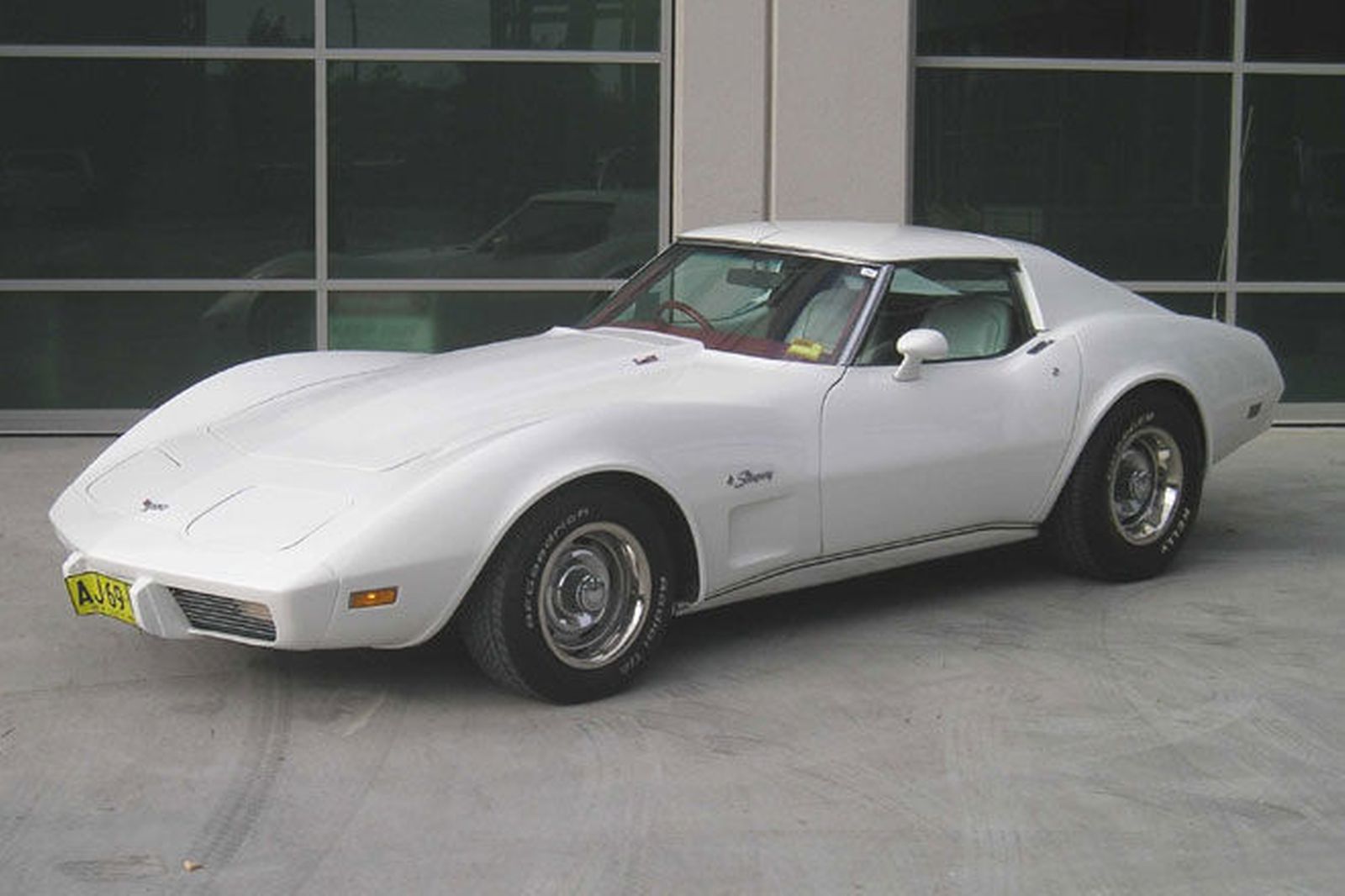

Stylistically, the 1976 Corvette was the best looking of the C3 Corvettes to date. While the changes to the exterior were minor, they were significant from an aesthetics standpoint.

To start, the air-extractor vents were removed from the rear deck. These vents, which had been part of the C3 Corvette since 1968 (they served as the exhaust mechanism for Corvette’s Astro-Ventilation system,) were eliminated along with the ventilation system itself.

Similarly, the 1976 Corvette’s hood no longer featured a cowl flap. The former hood’s cowl flap had become the center of consumer complaints which stated that the assembly whistled loudly during vehicle operation.

In place of the cowl flap, a simpler system was developed that rammed in airflow through a duct that ran forward over the radiator support to pick up some of the outside air that fed the radiator.

Even though the cowl-induction system had been eliminated for 1976, the intake grille remained for another year, and would not be deleted until 1977.

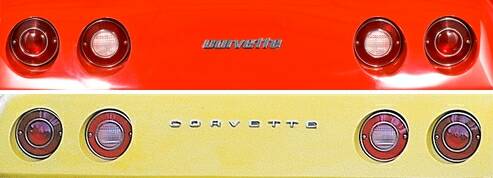

Moving to the rear of the Corvette, Chevrolet introduced two different styles of rear bumper/fascia assemblies. The first fascia was actually a carryover from the 1975 model year and featured the word “CORVETTE” in a large font that filled the width of the surface area between the rear headlights. The second, which was introduced in 1976, featured the word “CORVETTE” in smaller, recessed letters.

Perhaps the most notable change for 1976 was the re-introduction of the aluminum wheels that had first been introduced in 1973. Listed as option RPO YJ8, the set of four aluminum wheels (the 1973 option had actually included a fifth full size wheel as a spare) sold at an additional cost of $299.00 for the set, and included a conventional steel spare wheel/tire assembly. The wheels were manufactured by Kelsey Hayes in Mexico and could be identified by the source and build location information etched on their inside surface.

The interiors of the 1976 Corvette were largely unchanged from the previous year with one, notable exception. The interior now featured a four-spoke, “sport” steering wheel, though it was an option not well received by Corvette enthusiasts due mostly to the fact that the new steering wheel was the same as those being installed on the subcompact Chevy Vega GT, along with a number of other Chevrolet models that year.

Another change to the Corvette’s interior that was more widely accepted was the inclusion of the custom interior trim package (including leather seats) as part of the car’s base package.

Beneath the car, a partial steel subsection was added to the forward body structure. This steel under pan was added in an effort to increase the car’s rigidity and to act as a heat shield/insulator between the Corvette’s catalytic converters and the vehicle cockpit. While the catalytic converter was a concern to some engineers, it was actually a benefit to others. As a result of the catalytic converter being installed, the horsepower rating of the 1976 Corvette actually increased slightly.

The L48 engine saw an increase of 15 horses, pushing its total horsepower to 180bhp. The L82 increased up to 210bhp. Unfortunately, the L82 engine was not offered in California in 1976 (and 1977) because it did not meet the state’s tougher emissions standards. Four-speed manual transmissions were also banned out west for those same model years.

Interestingly, an automatic transmission was the only option available to Californians in 1976 (and 1977). However, it wasn’t the Turbo Hydra-Matic 400 that had been previously used behind all Corvette engines. Instead, Chevrolet mandated use of the less robust TH 350 automatic transmission. This choice was made because product planners felt that using the more expensive 400 transmission was overkill, especially given the limited amount of power that the L48 engine produced. The TH 400 remained the transmission of choice whenever a Corvette equipped with the L82 was ordered with an automatic transmission

Elsewhere, there were other mechanical revisions to the C3 that also helped improve performance, helped reduce weight and further helped the horsepower boost experienced on the 1976 Corvette.

Power steering and power brakes became standard on all 1976 Corvettes midway through production (though 173 early-production Corvettes hit the streets without power steering). Chevrolet introduced a lighter (by approximately 13 pounds) Delco Freedom battery as standard piece of equipment.

The Corvette also featured the aforementioned modified cowl induction, which was as much a functional benefit to the car’s overall performance as it was an aesthetic revision to the Corvette’s hood. Since pull air through an intake that was located in front of and above the radiator instead of at a more restrictive cowl located near the windshield, the 1976 Corvette could now breathe more easily.

Production Volumes

Unfortunately for consumers, Corvette’s price had risen again for 1976. It had increased over the previous model years because of the sharp inflation that had plagued consumers since the start of the global energy crisis in 1973. In 1976, consumers could purchase a base coupe (without any options) for $7,604.85. However, if the car were purchased with a full complement of options (as many were), it was possible to spend more than 10 grand (including ancillary charges) for the first time in Corvette’s history.

Still, although the price of the Corvette was at an all-time high, the new Corvette was still in high demand, as reflected in the fact that Chevrolet sold 46,558 units that year, breaking the previous sales record set in 1969.

It has been debated that this continued increase in Corvette sales in 1976 was a direct result of the energy crisis earlier in the decade. Many automotive manufacturers had eliminated their performance-car production lines completely, forcing consumers to turn to Chevrolet and the 1976 Corvette as a result. While some critics have speculated that this was the primary reason for the Corvette’s sales strength that year, there was still no denying that the Corvette was a unique and satisfying sports car – even at the higher price point.

1976 Corvette Specifications & Performance

See the complete breakdown of technical specifications for the 1976 Corvette, including engine, suspension, brakes, body dimensions, and power. Read more: 1976 Corvette Specifications.

Engine & Transmission

Like the previous year, the Corvette was offered with two engine options – both were 4-barrel 350 CID V8s. The big-block V8s had been discontinued in 1974. But there were some power gains as Chevy continued to work with the catalytic converters that had been introduced the previous year. The base model was up to 180 horsepower from 165 the year before, and the L82 version increased from 205 horsepower to 210.

Performance

Road and Track tested the 1975 Corvette and hit a horrible 7.4 second 0 – 60 mph time, with a even poorer 15.2 second quarter mile time. More (poor) performance details here.

1976 Corvette Vehicle Identification Numbers (VIN)

The last six digits begin at 400001 and run through 446558, accounting for 46,558 Corvette Coupes built in 1976. Each Vehicle Identification Number (VIN) is unique to an individual car. There is documented evidence that the final VIN for the 1976 Corvette ended in 446567, nine more units than the published total of 46,558. For all 1976 Corvettes, the location of the Vehicle Identification Number (VIN) is stamped on a plate attached to the left front body hinge pillar. Read more: 1976 Corvette VINs.

1976 Corvette Price & Options

Core Features & Factory Options

There were few changes in the 1976 Corvette, as engineering resources were occupied with meeting the demands of safety and pollution requirements while still managing to keep the character of the Corvette intact. The base engine horsepower rating was boosted 15 hp to 180 hp, marking the start of a long slow comeback to the performance of past years.

Of the few changes made to the car in 1976 that many critics mention is the new four-spoke-steering wheel. Perhaps the main point of contention against the steering wheel is that it was borrowed from Chevy’s Vega GT. This didn’t sit well with many Corvette enthusiasts at the time, and doesn’t go down well with many of them now. It’s probably a good thing this steering wheel only lasted a year.

Colors

Exterior colors for 1976 included Classic White 10,674 (22.93%), Silver 6,934 (14.89%), Bright Blue 3,268 (7.02%), Dark Green 2,038 (4.38%), Mahogany 4,182 (8.98%), Bright Yellow 3,389 (7.28%), Buckskin 2,954 (6.34%), Dark Brown 4,447 (9.55%), Orange Flame 4,073 (8.75%) and Red 4,590 (9.86%). More 1976 color information.

Pricing & Options

| CODE: | DESCRIPTION: | QUANTITY: | RETAIL PRICE: |

| 1YZ37 | Base Corvette Sport Coupe | 46,558 | $7,604.85 |

| — | Custom Interior Trim | 36,762 | $164.00 |

| A31 | Power Windows | 38,700 | $107.00 |

| C49 | Rear Window Defogger | 24,960 | $78.00 |

| C60 | Air Conditioning | 40,787 | $523.00 |

| FE7 | Gymkhana Suspension | 5,368 | $35.00 |

| — | Optional Rear Axle Ratios | 1,371 | $13.00 |

| J50 | Power Brakes | 46,558 | $59.00 |

| L82 | 350ci, 210hp Engine | 5,720 | $481.00 |

| M21 | 4-Speed Manual Trans, Close Ratio | 2,088 | $2,088.00 |

| M40 | Turbo Hydra-Matic Automatic Transmission | 36,625 | $0.00 |

| N37 | Tilt Telescopic Steering Column | 41,797 | $95.00 |

| N41 | Power Steering | 46,385 | $151.00 |

| QRM | White Stripe Steel Belted Tires, GR70x15 | 3,992 | $37.00 |

| QRZ | White Letter Steel Belted Tires, GR70x15 | 39,923 | $51.00 |

| U58 | AM-FM Radio, stereo | 34,272 | $281.00 |

| U6 | AM-FM Radio | 11,083 | $187.00 |

| UA1 | Heavy Duty Battery | 25,909 | $16.00 |

| UF1 | Map Light (on rearview mirror) | 35,361 | $10.00 |

| YF5 | California Emission Test | 3,527 | $50.00 |

| YJ8 | Aluminum Wheels (4) | 6,253 | $299.00 |

Read more: 1976 Corvette pricing and factory options.

1976 Corvette Gallery

When it comes down to it, the 1976 Corvettes were barely different from the 1975 Corvette, which in turn were not very different from the 1974 models. See full 1976 Corvette Image Gallery

I’m reading all the articles for each C3 model year (great work! thank you for making this available!), and I have a question about the ’76. A few of the photos show upswept tails, though I believe I recall the ’74 article noting that’s when they started the downswept tail design. I’m just curious if this was an option, a modification, or even a photo mistake.