Today we are going to take a deep dive into the transmission setup Carl will be using for this 10-second turbo C3, including custom coding from Carl for the transmission controller. Carl also provides another wild video, with the custom-coded controller working flawlessly with the turbo-charged LS engine and transmission. But, let’s not get ahead of ourselves! If you missed the previous two episodes, click here for part one, and here for part two. Each episode is a fairly quick read, with lots of pictures, and episode two has our first start-up video showcasing that monster turbo!

Viewer Advisory: This build has some serious meat on the bones, as Carl has some crazy technical skills (especially with electronics), and he is going to tap into all of them to turn his 1977 Stingray into a 10-second quarter-mile monster.

Here are the plans Carl has for his Stingray’s transmission:

“I chose a 4L80E because of the overdrive and high hp capabilities. It weighs more than other transmissions, but I’m not trying to set records. I bought a 2006 trans that was supposed to be good, but it definitely had issues. I bought a few more cores (2002 and 2004) dirt cheap, $100 and $150, so I can build the trans up myself.”

First, Carl built an adapter that lets him use the engine stand.

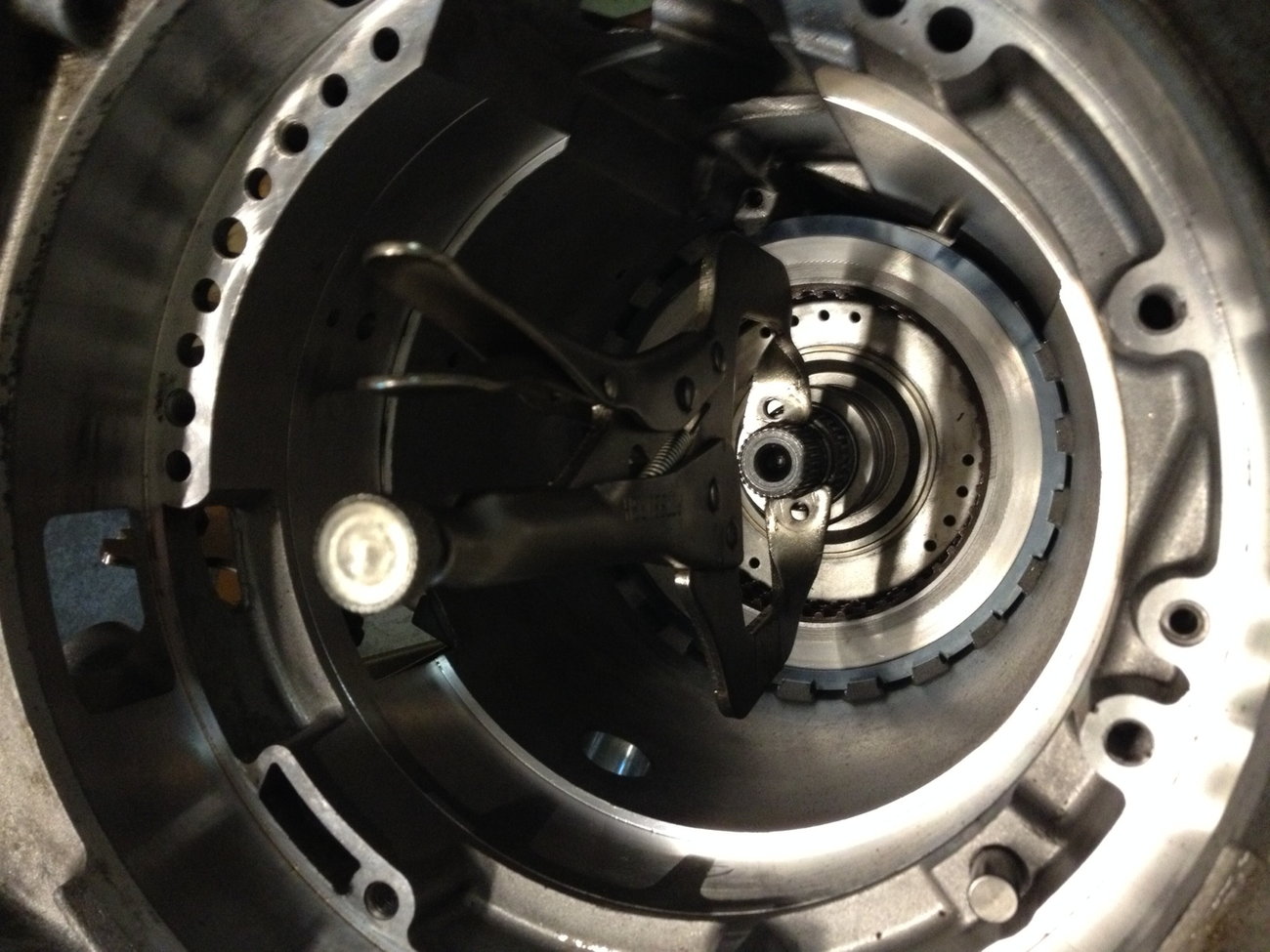

Then built a jig to decompress the direct and forward clutches.

And here’s his modified welding clamp to help manage the final drive assembly.

Carl searched through a number of boards and found that there was a ton of information about modifying these transmissions, and this is his complete rundown of the experience:

“I found that some guys who are in the business, provide some info, but most of the time they are vague, incomplete or meant to scare people into not working on the trans themselves. Then there were a few guys who were knowledgeable and straightforward that gave what I felt was clear guidance, ideas and photos.

Based on an exhaustive search through their posts, I’m doing the following mods to get my trans to handle about 750hp. It seems 750 is the magic number where you can get by with a few inexpensive parts. Over 750, you need to swap many parts for billet.

The two most important mods appear to be to dual feed the direct clutch and the Large Ratio Boost valve sonnax 4L80E-LB1. Dual feed provides more fluid to clamp the clutches used for 3rd gear. The large ratio boost valve provides higher maximum line pressure to clamp the clutches and bands tighter while still maintaining a reasonably low line pressure when cruising.”

In addition, Carl is also doing these modifications and tasks:

*Actuator Feed Limit repair kit transgo 48-ACT-TL

*Line to Lube Pressure Regulator Valve Sonnax 34200-14K

*Torlon Check Balls (you need 8) sonnax 10000-08

*No Walk Case Busing sonnax 34006-SP

*Replace rear case bushing with torrington bearing

*More clutches in the direct drum

*Increasing the size of the feed holes for 1st, 2nd and 3rd

*Remove and block the 3rd gear accumulator

*Drill larger pump seal drain hole

*Replace any worn bushings, seals and gaskets

He has put together a notebook with photos, charts, and torque specs from the web, and acquired the ATSG manual. Then Carl confidently comments, “Transmissions are the best jigsaw puzzle ever.”

Carl begins assembling the puzzle and notes, “One of the issues fitting a 4L80E in a c3 are the cooler lines. Stock fittings stick straight out and would not fit in the tunnel. I cut the ends off the stock fittings and welded on right angle Swagelock (just cause I happened to already have then in my junk pile) fittings.”

The Transmission Controller

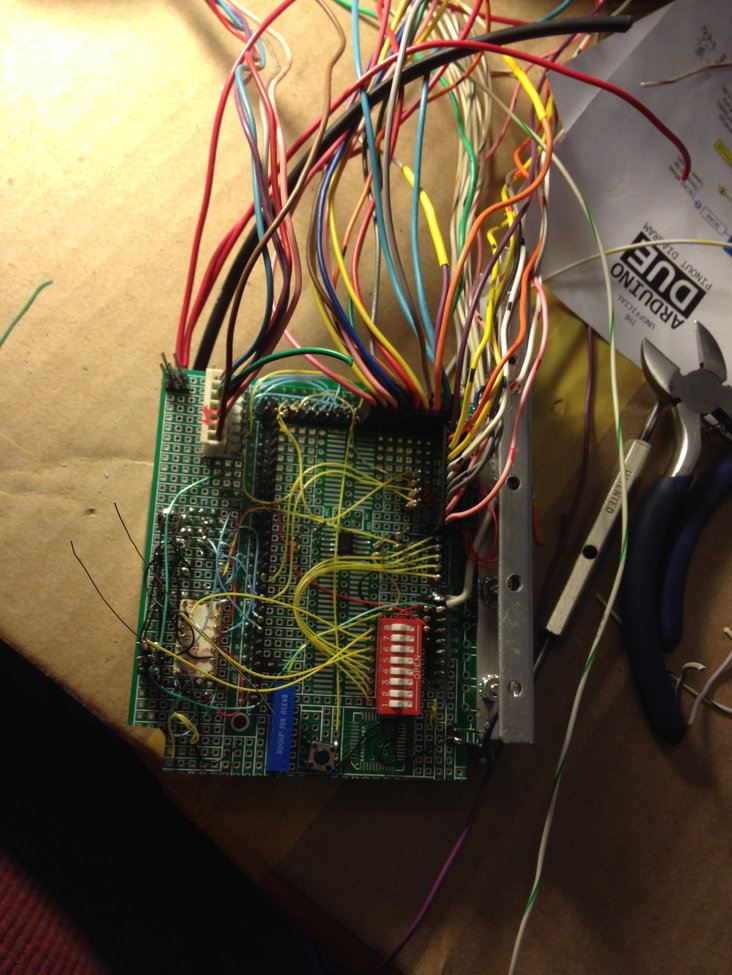

With this next project, Carl admits he went a little overboard, as he designs and builds a controller for his built 4L80E transmission. Here are the details, straight from Carl:

“The controller processor is an Arduino board. Started off with plans of making a simple controller and then, like the rest of this corvette project, I had a major case of scope creep and kept adding features.

First I added the required set of peripheral components like VR sensor for MPH, drivers for the solenoids, map sensor etc.

Then I added a display panel and some buttons and an Xbox Controller Joystick. The control panel doubles as a dashboard and a way of changing shift, boost and other parameters. Then I added more sensors. The trans controller also serves as a boost controller.

So I went a little crazy and created a bunch of driving modes. Each driving mode has it’s own shifting and boost characteristics.

For cruising around, there is Cruise mode. Cruise mode shifts based on MPH and load (vacuum/boost). Cruise mode can use all 4 gears and lockup. Shift tables for each gear/load can be changed from the control panel. Rules are in place to protect against downshifts that will overrev the engine and also shift up a gear in case the engine exceeds the maximum rev limit. Each gear also has a target boost. Line pressure is controlled by load and mode.

Some other modes, Burnout mode. Only shifts based on engine RPM and only goes up to a preset gear. When the burnout is done, the controller automatically changes to Drag mode. Drag mode also shifts by RPM and only shifts up to 3rd gear. No 4th, no lockup. Drag mode also has a target boosts for each gear.

There is also a Dyno mode and a joystick (similar to paddle shift) mode.

The controller also logs maximum/minimum values and alarms.

Display shows gear, mph, rpm, oil pressure, fuel pressure, boost/vacuum, boost target for current gear, oil temp and engine temp on the primary display. There is a switch to toggle in 2 additional displays for things like line pressure, trans temp, and max/minimum readings reached.

I built a simulator using another Arduino board to test as much as possible before it goes in the car.

I have no intentions of making a product of this. It’s a hobby and I’ve ruined some of my other hobbies by turning them into business before.”

Wow, Carl, your skills are simply amazing. The complexity of this controller seems utterly daunting, and even Carl concedes, “I felt a little dizzy when I was writing the code. I’m still dizzy.”

Now, without further ado, here is Carl’s video showing his custom-coded controller working harmoniously with the 4L80E transmission and turbo-charged LS engine. What a masterful assembly!

I hope you are enjoying this highly detailed build and what Carl has in store for us next! As always, we have an active community on our Facebook page, I would love to see you there! Douglas B.