1971 Corvette – The Ultimate Guide

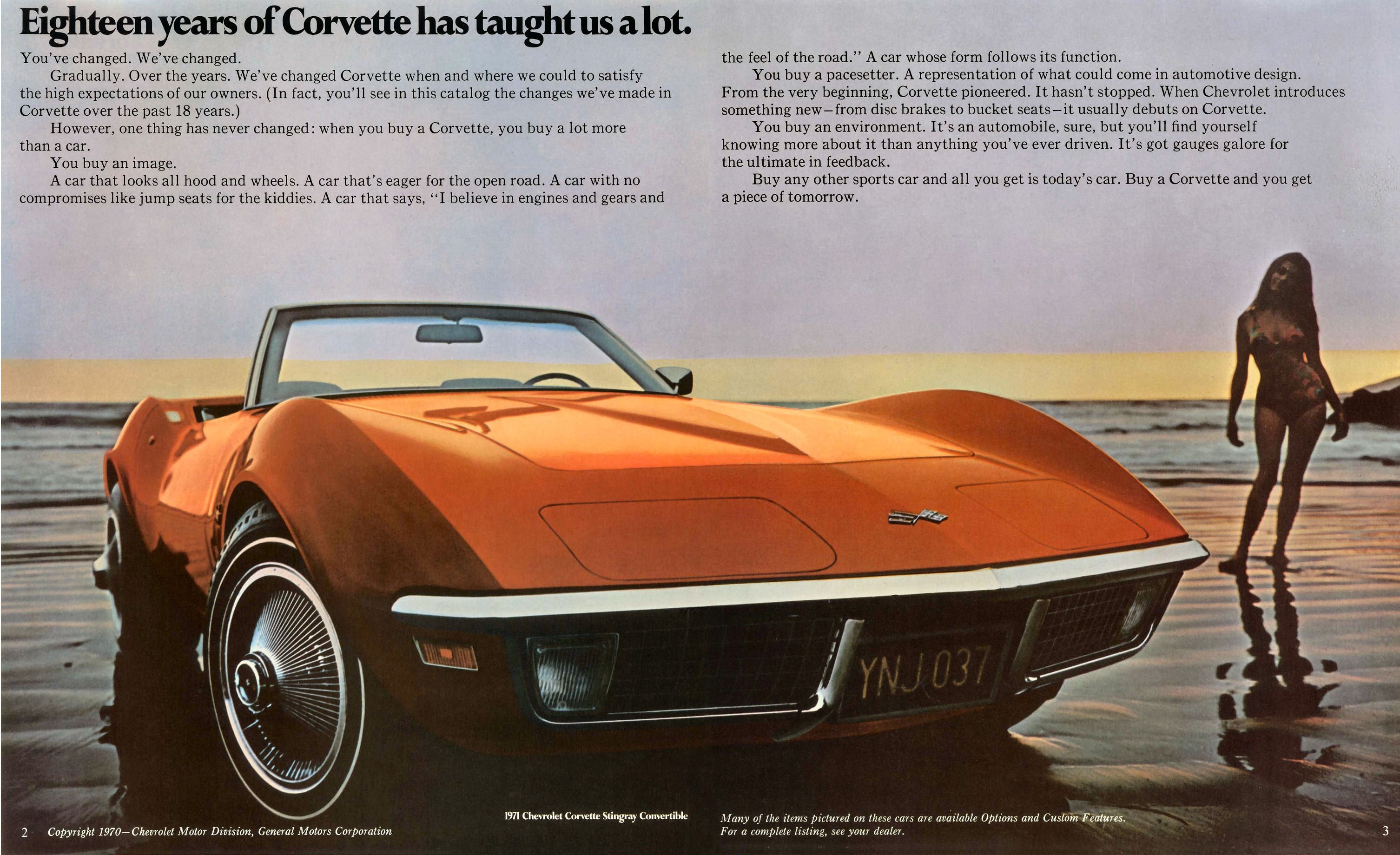

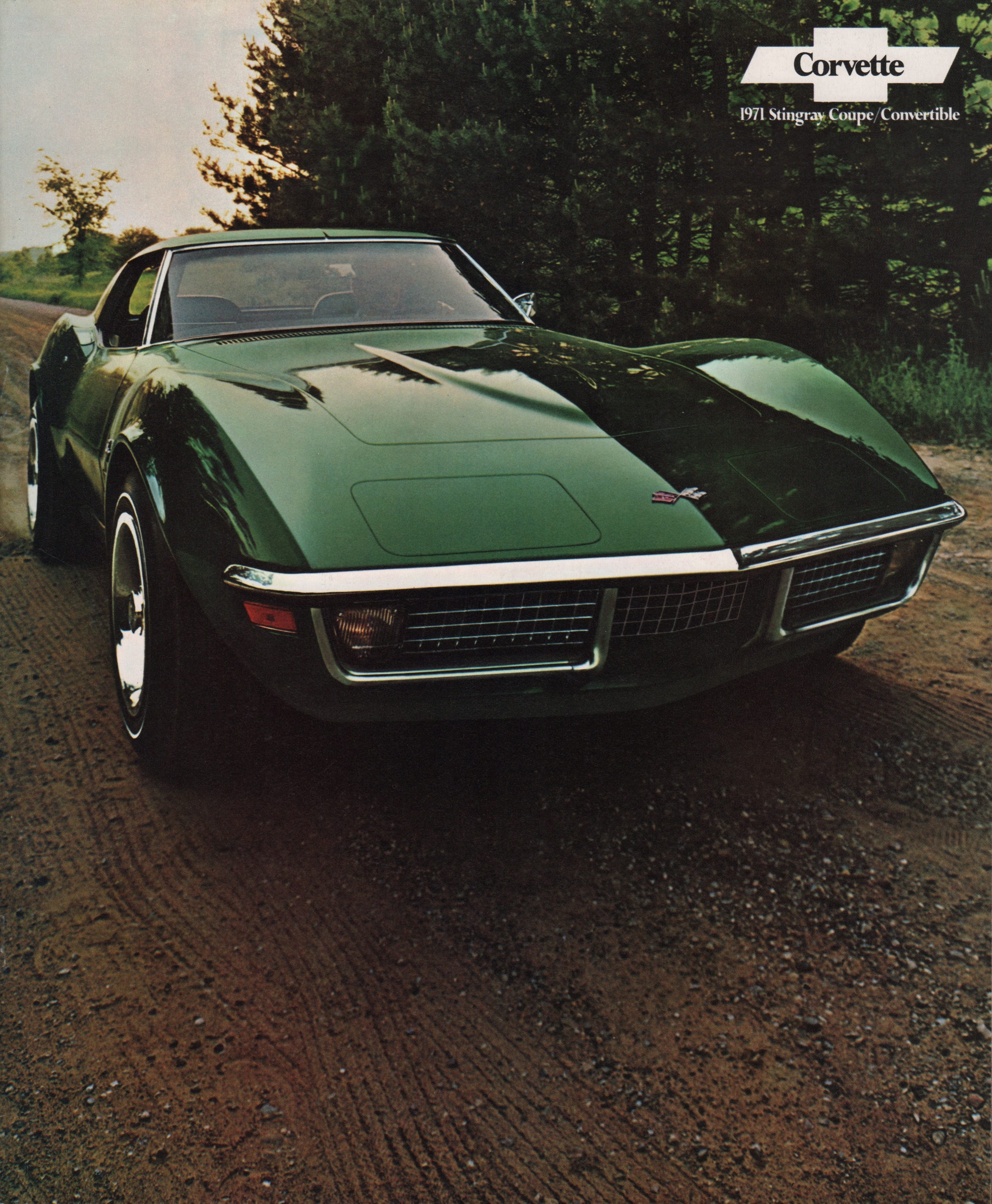

The 1971 Chevy Corvette remains one of the least changed models in design (when compared to the preceding model year) in Corvette’s entire production history.

The United Auto Workers (UAW) labor dispute that occurred in May, 1969, which had caused the 1969 model year to run over by two months, had also shorted production of the 1970 Corvette by over four months.

Because of this, it was decided by Chevrolet management that they should treat the 1971 model year as an extension of the 1970 line, which meant that the Corvette – for better or worse – would remain essentially unaltered between the two model years.

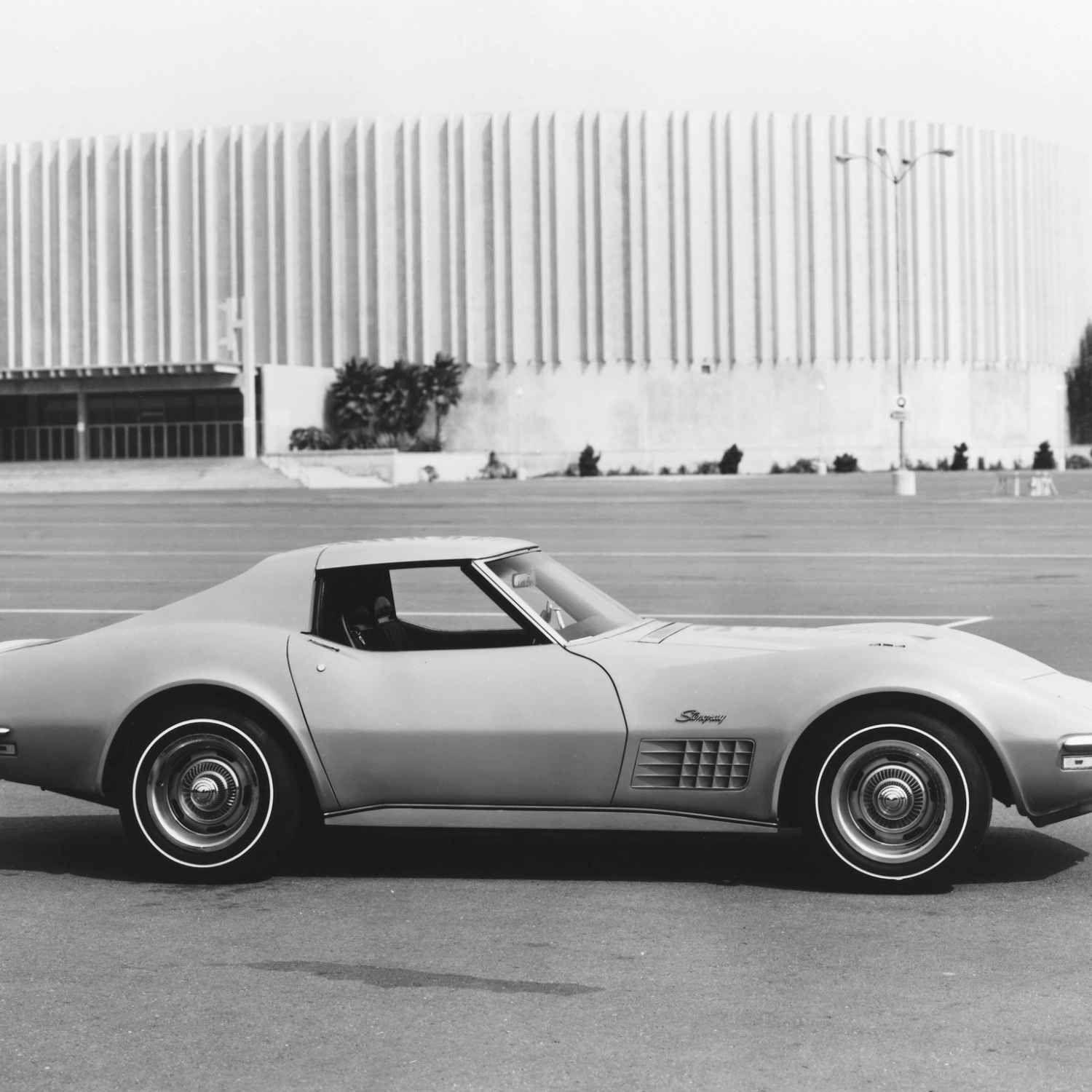

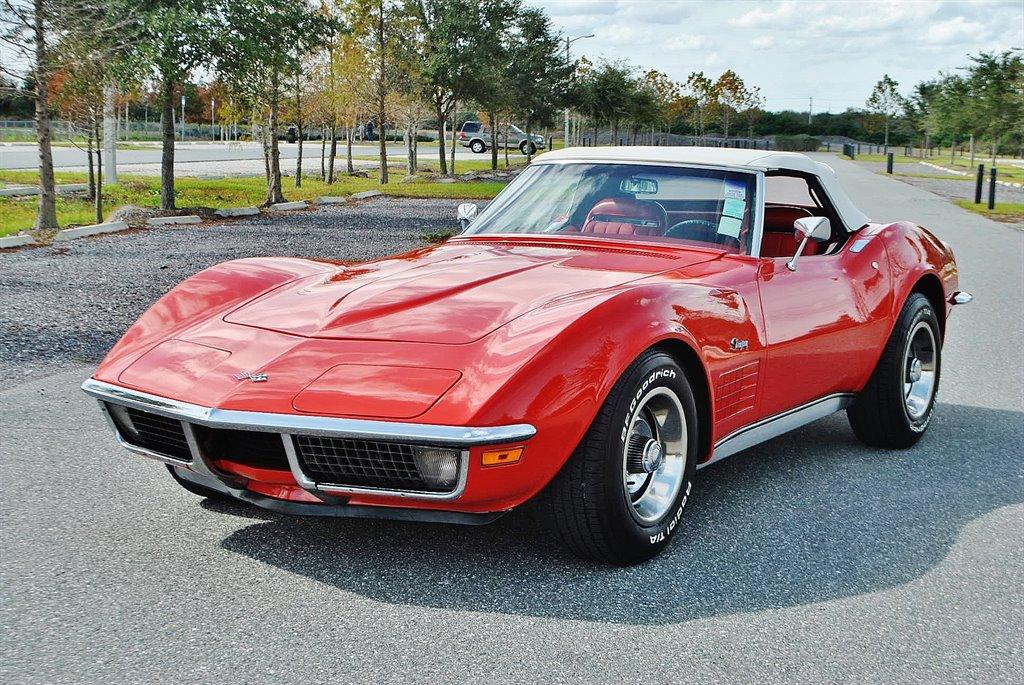

The 1971 Corvette was virtually unchanged from 1970. (Image courtesy of GM Media.)Because the production of the cars would remain virtually unchanged from 1970 to 1971, production lines in the St. Louis Corvette plant were able to work in earnest to produce – to create – a more trouble-free car. In fact, the (more than) 500 men and women that worked each shift at the Corvette plant were highly motivated to build a better machine, knowing that they were fortunate not to be part of the many facilities across the country that mass-produced “faceless utility cars”, but rather a well-respected, much sought after sports car. Vince Shanks, the plant manager of the St. Louis Corvette Manufacturing Plant, was quoted as saying “When you ask a guy where he works in St. Louis, he’ll tell you ‘Corvette’ rather than ‘Chevrolet.’ Every Corvette he sees on the road is one he’s worked on. That’s quite an incentive.”

Because the production of the cars would remain virtually unchanged from 1970 to 1971, production lines in the St. Louis Corvette plant were able to work in earnest to produce – to create – a more trouble-free car. In fact, the (more than) 500 men and women that worked each shift at the Corvette plant were highly motivated to build a better machine, knowing that they were fortunate not to be part of the many facilities across the country that mass-produced “faceless utility cars”, but rather a well-respected, much sought after sports car. Vince Shanks, the plant manager of the St. Louis Corvette Manufacturing Plant, was quoted as saying “When you ask a guy where he works in St. Louis, he’ll tell you ‘Corvette’ rather than ‘Chevrolet.’ Every Corvette he sees on the road is one he’s worked on. That’s quite an incentive.”

The 1971 Corvette’s arrival also came in conjunction with a flurry of new federal regulations that forced manufacturers to reassess the types of cars they were producing.

In addition to the Federally sanctioned mandates on reducing exhaust emission outputs, Edward Cole (who was now president of General Motors) had decreed that all 1971 GM cars would be capable of running on fuel with a Research Octane Number (RON) no higher than 91 Octane.

According to Cole’s calculations, this octane rating was low enough for the fuel companies to begin marketing the lead-free regular gasoline needed to avoid fouling catalytic “reactors” (known as converters today) that were going to be required automobile engines. This reduction in fuel octane rating would translate into a reduction in engine compression (now just 8.5:1) and horsepower (a mere 270 bhp in the stock 350 engine.)

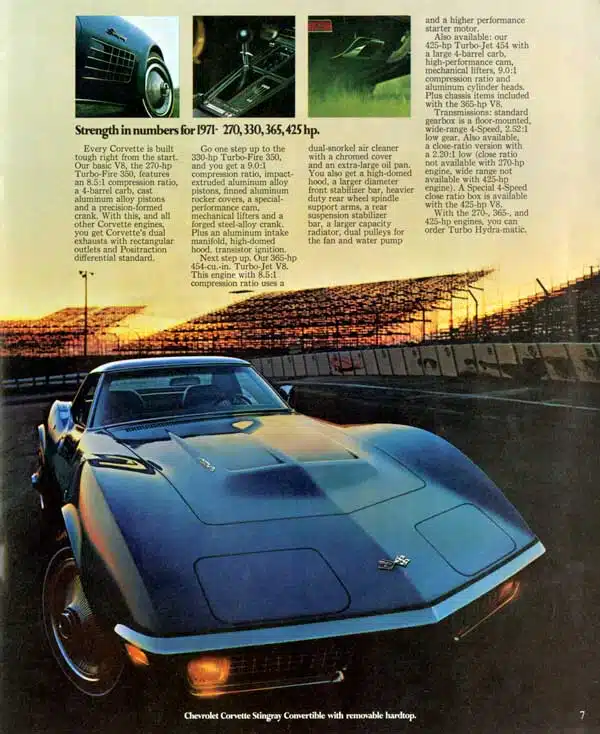

Somewhat surprisingly, these sanctioned emissions and fuel requirement changes didn’t only impact Corvette’s base engine. To the contrary, a notable reduction in compression – and power – was seen on almost all of the engines offered in the 1971 Corvette. The solid lifter, small block LT1 engine, which had boasted 370 horsepower in 1969, was now rated at a more modest 330 horsepower with a 9.0:1 compression ratio. The big-block engines also received the same treatment. The LS5 454 cubic inch big-block came equipped with 365 horsepower at 4800 rpm, and a new aluminum-head big-block engine identified as the LS6 was rated at 425 horsepower at 5600 rpm. Given the output numbers of these engines, there were few who would argue that the 1971 Corvette was weak, although most would agree that it was a far cry from the Corvettes that emerged in the unregulated era of muscle car performance.

Interestingly, the 1971 454 LS6 engine was actually a detuned version of 1970’s planned but cancelled 460 horsepower LS7. While the engines were fundamentally the same, the LS6 was developed to operate on low-lead, lower-octane fuel, giving it the clear marketing advantage over its never-to-be LS7 predecessor, despite its lower horsepower rating.

The LS6 engine featured aluminum heads, and its pistons were modestly domed, which helped it achieved the slightly higher 9.0:1 ratio. One unique feature for this high-performance big-block engine was that it could be ordered with an automatic transmission, although not when it was combined with the ZR2 package. Still, such an $1,220.70, and as such, only 188 were ever sold. Even Duntov, who had pushed for the development of the LS6, had later been quoted in Car & Driver as saying, “Maybe I make mistake. Aluminum heads are expensive and that weight (reduction) doesn’t matter on the street.”

Still, it was the right kind of engine to lead the Corvette lineup, and that was where it’s real marketing value mattered most.

Because of Cole’s far reaching directive, Chevrolet engineers had only a matter of weeks rather than months to adjust all of their engines – and not just those for the Corvette. Because of this, very few changes were made to the 1971 Corvette – other than those made to the engines.

DID YOU KNOW: The 1971 Corvette production specs called for the use of amber parking light lenses. However, most 1971 Corvettes came equipped with clear lenses and amber bulbs, which was a carry-over from the 1970 model year. Additionally, the 1971 Corvette included an optional custom interior trim package which included leather seat trim, wood-grain accents, and lower carpet trim on interior door panels, wood grain accents on the console and special cut-pile carpeting.

There were minor advances made, such as an easier-to-open fuel filler door, and an automatic transmission selector quadrant that illuminated during night time operation, but nothing that really separated the 1971 model from earlier years. However, the 1971 Corvette would be the last Corvette model to feature the fiber-optics light monitoring system, and it is believed that many late model 1971 Corvettes were actually manufactured without the fiber optics. (While not a notable change to the 1971 Corvette, the removal of the fiber-optic system allowed Chevrolet to make the optional anti-theft alarm system (RPO UA6) standard equipment for the 1972 model.)

For 1971, Chevrolet offered consumers not one, but two special purpose (racing) packages. The first of these was the RPO ZR1 package which utilized the aforementioned LT1 engine, and also included a heavy-duty, four-speed, close ratio transmission (RPO M22), heavy-duty power brakes, a special aluminum radiator, a metal fan shroud, a transistor ignition, and a revised suspension with special springs, shocks, spindle-strut shafts, and front and rear stabilizer bars (though it has since been determined that the 1971 ZR1 has appeared with and without rear stabilizers.) When equipped with the ZR1 package, consumers were unable to include many of the more “luxurious” amenities available power windows, a rear window defroster, air conditioning, power steering, deluxe wheel covers, an alarm system, and any type of AM/FM radio.

The second special purpose package that Chevrolet offered was RPO ZR2. This second special purpose package was identical to the ZR1, except that instead of a small block LT1 engine, the ZR2 came equipped with the aforementioned 454 cubic inch LS6 engine. Like the ZR1, the ZR2 package also included the same ordering restrictions – namely none of the “creature comfort” amenities that were appealing to many consumers.

It may be for that very reason – or perhaps that combined with the substantial cost increase that each option carried with it – that so few of either performance packages was ordered during that model year. In total, only eight Corvettes were ordered with the ZR1 option, and only twelve were ordered with the ZR2.

Beyond these items, the 1971 Corvette carried on much as its 1970 predecessor had. Pricing for the 1971 Corvette increased, though only modestly, to $5,259 for a convertible, and $5,496 for the coupe.

Production Volumes

With production now recovered from the UAW strike, sales of the 1971 Corvette improved, resulting in a total of 21,801 Corvettes sold for that model year, with the coupe taking a 2 to 1 sales lead over the convertible – a result which many believed was the result of the C3’s introduction of T-tops in 1969. Prior to that point, Corvette convertibles had actually dominated sales, but starting in 1969, more coupes than convertibles were sold with each model year that passed.

In 1971, the result was total coupes to just 7,121 convertibles – a fact that GM would take under serious consideration in the years to come, and also a fact that would lead to a shocking, and some consider controversial, decision for the 1976 model year.

1971 Corvette Specifications & Performance

See the complete breakdown of technical specifications for the 1971 Corvette, including engine, suspension, brakes, body dimensions, and power. Read more: 1971 Corvette Specifications.

Engine & Transmission

The power reduction was mainly a result of increasingly stringent government regulations designed to help control emissions standards, and all of the engine detuning was set into place to fit the requirement that all cars run on low-lead fuel. By the following year the cars would be required to run on unleaded fuel, and power would be further zapped. The base models were still using a 350 CID small-block V8, but the base engine was reduced from 300 horsepower to 270. A modified version of the small-block engine known as the LT1 also suffered a decrease in horsepower from 370 to 330.

Corvettes with the 454 CID big-block V8 also suffered, with the horsepower ratings dropping from 390 to 365. Maximum power, however, was saved with the introduction of the LS6, which was rated at 425 horsepower. But because the engine option added at least $1,200 to the base price (depending on which transmission was chosen), only 188 Corvettes were built with this engine. Even fewer (12) came with the new ROP ZR2 racing package. This package added an additional $1,747 to the base price, and 1971 would be the only year it was offered. There also was a ZR1 package that was used with the LT1 engine.

Performance

Popular Hot Rod recorded the quarter mile in 14.0 sec @ 95.64 mph (454ci/365hp), while Car Craft 8/71 managed it in 13.7 sec @ 102.0 mph in the 454ci/425hp set up. More on 1971 performance here.

1971 Corvette Vehicle Identification Numbers (VIN)

The last six digits begin at 100001 and run through 121801, accounting for all 21,801 Corvette Coupes/Convertibles built in 1971. Each Vehicle Identification Number (VIN) is unique to an individual car. Read more: 1971 Corvette VINs.

1971 Corvette Price & Options

Core Features & Factory Options

There also was a ZR1 package that was used with the LT1 engine. It included a heavy duty transmission, power brakes and a revised suspension. Because it was built purely for racing, it was not available with power windows, power steering, air conditioning or a radio. Because it also was expensive, the existence of this package is about as rare as the ZR2. More options here.

Colors

Exterior colors (and production splits) for 1971 included Nevada Silver 1,177 (5.40%), Sunflower Yellow 1,177 (5.40%), Classic White 1,875 (8.60%), Mille Miglia Red 2,180 (10.00%), Mulsanne Blue 2,465 (11.31%), Bridgehampton Blue 1,417 (6.50%), Brands Hatch Green 3,445 (15.80%), Ontario Orange 2,269 (10.41%), Steel Cities Gray 1,591 (7.30%) and War Bonnet Yellow 3,706 (17.00%). More detailed color information here.

Pricing & Options

The Base Corvette Coupe with 350 cu. in. 300 hp engine and wide ratio four speed manual transmission started at $5,496, while the Base Corvette Convertible with 350 cu. in. 300 hp engine and wide ratio four speed manual transmission started at $5,259.

| CODE: | DESCRIPTION: | QUANTITY: | PRICE: |

| 19467 | Base Corvette Sport Coupe | 14,680 | $5,496.00 |

| 19467 | Base Corvette Convertible | 7,121 | $5,259.00 |

| – | Custom Interior Trim | 2,602 | $158.00 |

| A31 | Power Windows | 6,192 | $79.00 |

| A85 | Custom Shoulder Belts (std with coupe) | 677 | $42.00 |

| C07 | Auxiliary Hardtop (for convertible) | 2,619 | $274.00 |

| C08 | Vinyl Covering (for auxiliary hardtop) | 832 | $63.00 |

| C50 | Rear Window Defroster | 1,598 | $42.00 |

| C60 | Air Conditioning | 11,481 | $459.00 |

| ZQ1 | Optional Rear Axle Ratio | 2,395 | $13.00 |

| J50 | Power Brakes | 13,558 | $47.00 |

| LS5 | 454ci, 390hp Engine | 5,097 | $295.00 |

| LS6 | 454ci, 425hp Engine | 188 | $1,221.00 |

| LT1 | 350ci, 330hp Engine | 1,949 | $483.00 |

| M21 | 4-Speed Manual Transmission, close-ratio | 2,387 | $0.00 |

| M22 | 4-Speed Manual Transmission, close ratio heavy duty | 130 | $100.00 |

| M40 | Turbo-Hydro-matic Automatic Transmission | 10,060 | $0.00 |

| N37 | Tilt-Telescopic Steering Column | 8,130 | $84.30 |

| N40 | Power Steering | 17,904 | $115.90 |

| PO2 | Deluxe Wheel Cover | 3,007 | $63.00 |

| PT7 | White Stripe Tires, F70x15 nylon | 3,007 | $63.00 |

| PU9 | White Letter Tires, F70x15 nylon | 6,711 | $28.00 |

| T60 | Heavy Duty Battery (std with LS5) | 12,449 | $42.00 |

| UA6 | Alarm System | 1,455 | $15.80 |

| U69 | AM-FM Radio | 8,501 | $31.60 |

| U79 | AM-FM Radio, stereo | 18,078 | $178.00 |

| ZR1 | Special Purpose LT1 Engine Package | 8 | $1,010.00 |

| ZR2 | Special Purpose LS6 Engine Package | 12 | $1,747.00 |

Read more: 1971 Corvette pricing and factory options.

1971 Corvette Gallery

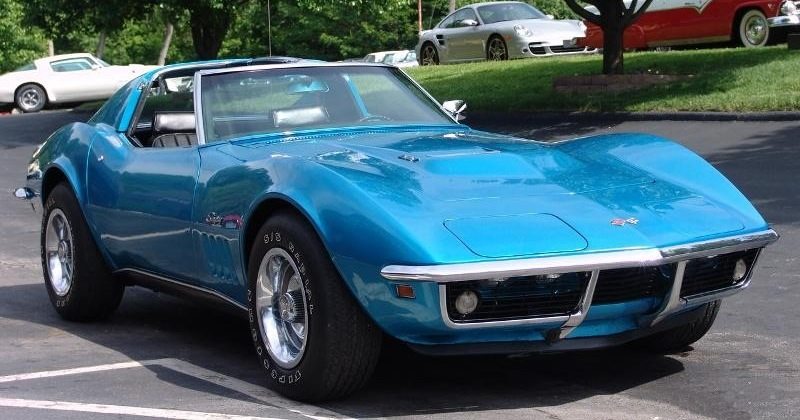

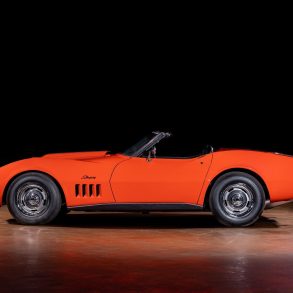

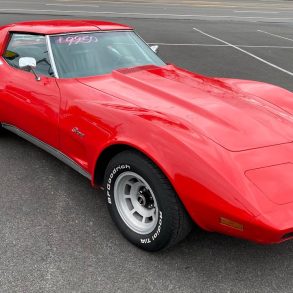

All in all, the 1971 Corvettes were nearly identical to the 1970 models that had come before it. Styling changes were nearly non-existent, and visually it was all but impossible to distinguish between the two models. See full 1971 C3 Corvette Image Gallery

I hope I can ask a question, is there knowledge of how many 1971 corvettes in Miliga Red with Red interior were built that year.

I’m looking at a 1971 coupe, it may have been a big block at one time. How can I tell i

Hi I’m looking at a 1971 corvette coupe. I’m told it may have been a big block car originally. How can I tell if it was an original 454 ci?